11.2. Track_LM Tutorial (eTemplate)

11.2.1. Getting Started

In this tutorial, the cells for Header Type and Parameter Definition cell are colored, but the color doesn’t affect the data at all.

Once after an eTemplate model (Excel file) is imported to RecurDyn, a new model needs to be created to import another eTemplate model (or a modified model).

This tutorial provides the Excel data to be copied and pasted. You can copy and paste the data with the left scissors mark to the Excel sheet

11.2.1.1. Objective

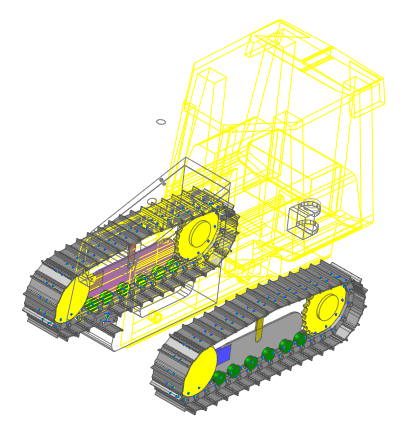

In this tutorial, you will make eTemplate model (Excel file) for Low-mobility tracked vehicle. Firstly you will use Master sheet of eTemplate model and HC (Hierarchy Connector). And you will create track system using eTemplate, and simulate it.

11.2.1.2. Audience

This tutorial is intended for intermediate users of RecurDyn who previously learned how to use TrackLM toolkit and basic operation of the Microsoft Excel.

11.2.1.3. Prerequisites

You should first work through the 3D Crank-Slider and Engine with Propeller tutorials, or the equivalent and TrackLM tutorial. We assume that you have a basic knowledge of physics.

11.2.1.4. Procedures

The tutorial is comprised of the following procedures. The estimated time to complete each procedure is shown in the table.

Procedures |

Time (minutes) |

Modifying Template_Format Sheet |

5 |

Using Master Sheet |

10 |

Creating Track_HC Sheet for eTemplate HC |

10 |

Creating bodies |

10 |

Creating track assembly |

10 |

Creating joints |

10 |

Changing settings |

10 |

Importing eTemplate file and running simulation |

10 |

Total |

75 |

11.2.1.5. Estimated Time to Complete

This tutorial takes approximately 75 minutes to complete.

11.2.2. Modifying Template_Format Sheet

11.2.2.1. Task Objective

Learn how to modify the Template_Format Sheet

11.2.2.2. Estimated Time to Complete

5 minutes

11.2.2.3. Modifying Template_Format Sheet

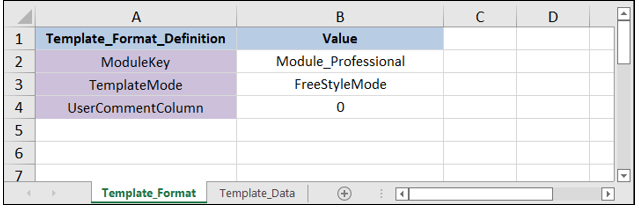

11.2.2.3.1. To modify Template_Format Sheet

- On your Desktop, open the eTemplate file which exists in the same folder with this tutorial. ([eTemplate]Track_LM_Tutorial_Default.xlsx)(The file path: <InstallDir>\Help\Tutorial\eTemplate\CreationMode\TrackLM)

This file is the base file of eTemplate, which has the Template_Format Sheet. The purpose of this sheet is to decide how to handle this file.

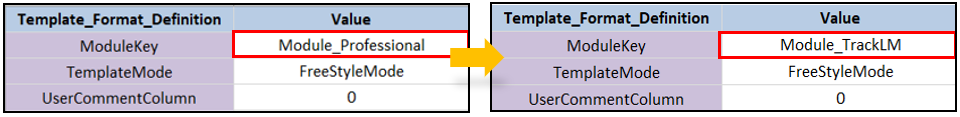

You should modify the ModuleKey setting to use this eTemplate file for Track_LM. Type Module_TrackLM instead of Module_Professional

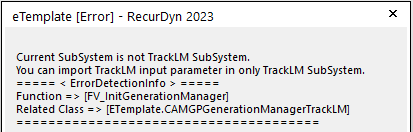

Now, this eTemplate file can be imported in TrackLM subsystem. But if you try to import this eTemplate file in other type of subsystem such as TrackHM or Chain, the below error message will be shown.

Tip

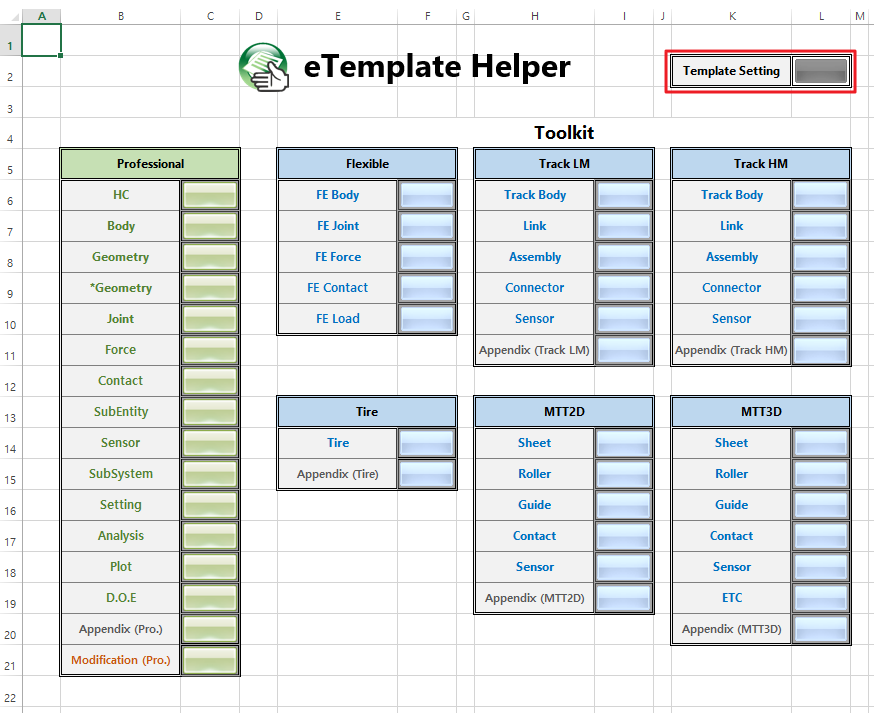

Copying the header and parameters using the eTemplate Helper

On the Customize tab, in the eTemplate group, click the Helper function to run the eTemplate Helper.

Click the Template Setting button.

Copy the header and parameters of the Template_Format sheet to the template.

Edit the values so that they fit the tutorial.

11.2.3. Using Master Sheet

11.2.3.1. Task Objective

Learn how to use Master Sheet

11.2.3.2. Estimated Time to Complete

10 minutes

11.2.3.3. Using Master Sheet

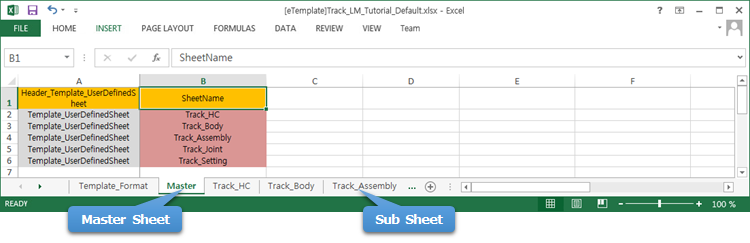

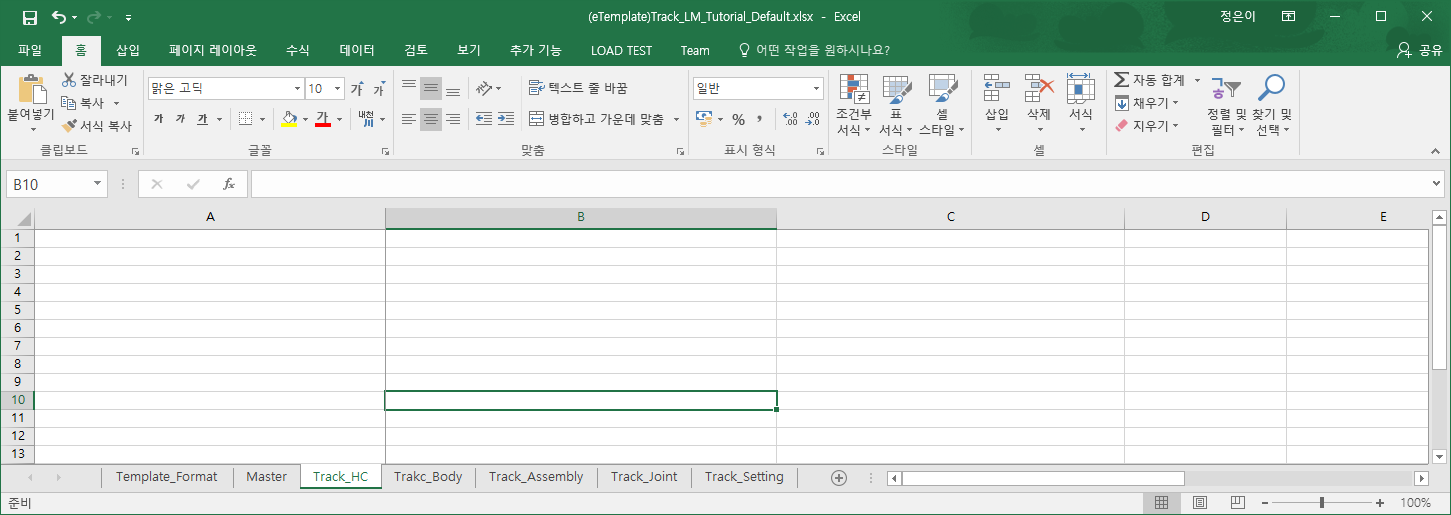

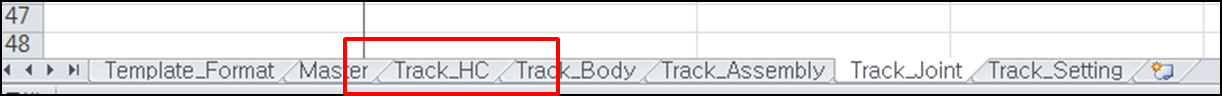

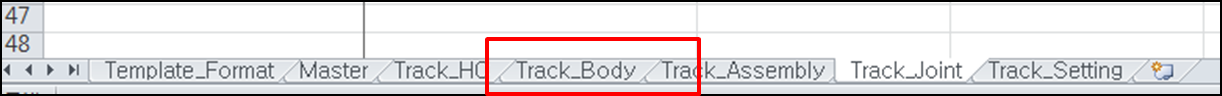

In this chapter, you will create several sheets to input many data systematically and you will create master sheet to handle several sheets. You will create the below sheets

Track_HC

Track_Body

Track_Assembly

Track_Joint

Track_Setting

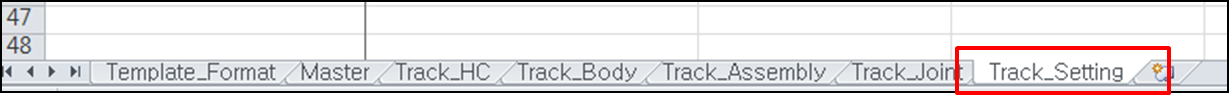

You can find Master Sheet next to Template_Format sheet. And this Master Sheet will include the information of the sheets which are used in this eTemplate model as below.

11.2.3.4. Editing Master Sheet

11.2.3.4.1. To use master sheet

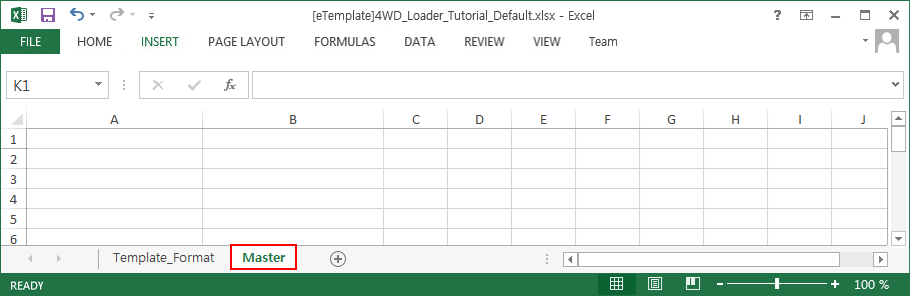

eTemplate file must have Master Sheet. This tab is essential for RecurDyn to import an eTemplate file. So you must not remove or rename this sheet.

11.2.3.4.2. To edit sub sheets

You will create 5 sheets.

Add 5 sheets in the Excel file and rename them (Track_HC, Track_Body, Track_Assembly, Track_Joint, Track_Setting)

11.2.3.4.3. To edit Master Sheet

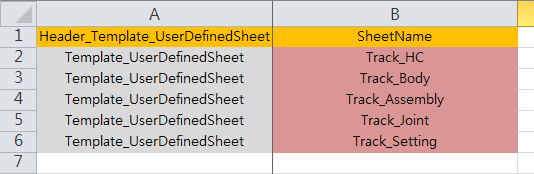

To control sub sheets, Master Sheet must have Headers and Parameters.

Input Header_Template_UserDefinedSheet as Header Type and input SheetName as Parameter Type.

Input headers and parameters as below

Header_Template_UserDefinedSheet

SheetName

Template_UserDefinedSheet

Track_HC

Template_UserDefinedSheet

Track_Body

Template_UserDefinedSheet

Track_Assembly

Template_UserDefinedSheet

Track_Joint

Template_UserDefinedSheet

Track_Setting

The below image shows the Excel data after the above data are input.

Please pay attention that the names used for parameters are same to the names of the sub sheets.

11.2.4. Creating Track_HC Sheet for eTemplate HC (Hierarchy Connector)

11.2.4.1. Task Objective

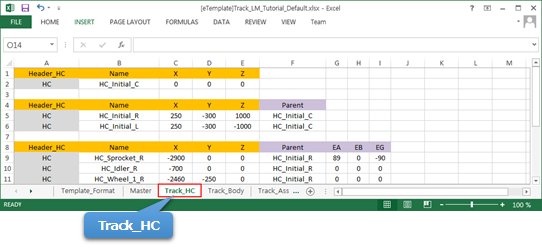

In this chapter you will learn how to create eTemplate HC (Hierarchy Connector) to be used in the later chapters. The data will be input in Track_HC Sheet

11.2.4.2. Estimated Time to Complete

10 minutes

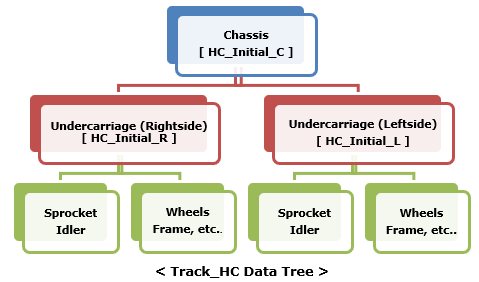

11.2.4.3. Understanding Track System

11.2.4.3.1. To construct Track System

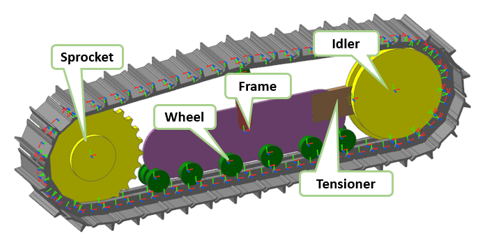

Track System can be roughly divided into 3 parts. Chassis, Undercarriage (Right side), Undercarriage (Left side).

HC (Hierarchy Connector) is used to define the relative position and orientation.

In this tutorial, HCs are defined relative to the position of Chassis. In other words, if the position of Chassis is moved, the entire Track System is moved.

11.2.4.4. Editing Track_HC Sheet

11.2.4.4.1. To input data in Track_HC Sheet

Select Track_HC Sheet.

Input HC_Initial_C for the position of Chassis. This will be used as reference position of the entire Track System.

Header_HC

Name

X

Y

Z

HC

HC_Initial_C

0

0

0

Input HC_Initial_R and HC_Initial_L for undercarriages. Parent means that the position of these HCs are relative to HC_Initial_C.

Header_HC

Name

X

Y

Z

Parent

HC

HC_Initial_R

250

-300

1000

HC_Initial_C

HC

HC_Initial_L

250

-300

-1000

HC_Initial_C

Now you will Input the other HCs as below for the components of the right side undercarriage. So the parent must be HC_Initial_R.

For sprocket, position and orientation need to be defined to avoid the interference between the teeth of Sprocket and track links.

Header_HC

Name

X

Y

Z

Parent

EA

EB

EG

HC

HC_Sprocket_R

-2900

0

0

HC_Initial_R

89

0

-90

For the other parts except sprocket, only position needs to be input.

Header_HC

Name

X

Y

Z

Parent

HC

HC_Idler_R

-700

0

0

HC_Initial_R

HC

HC_Wheel_1_R

-2460

-250

0

HC_Initial_R

HC

HC_Wheel_2_R

-2220

-250

0

HC_Initial_R

HC

HC_Wheel_3_R

-1930

-250

0

HC_Initial_R

HC

HC_Wheel_4_R

-1640

-250

0

HC_Initial_R

HC

HC_Wheel_5_R

-1350

-250

0

HC_Initial_R

HC

HC_Wheel_6_R

-1110

-250

0

HC_Initial_R

HC

HC_Carrier_Roller_1_R

-1780

360

0

HC_Initial_R

HC

HC_Tensioner_R

0

0

0

HC_Initial_R

HC

HC_Frame_R

0

0

0

HC_Initial_R

HC

HC_Frame_Fixed_R

-1780

0

0

HC_Initial_R

HC

HC_Tensioner_Fixed_R

-1200

0

0

HC_Initial_R

In this time, you will input data for left side undercarriage. Here you can find the advantage of using eTemplate. To create left side undercarriage, you just need to copy and paste the data for right side undercarriage and just change the Parent from HC_Initial_R to HC_Initial_L and change the HC Name R to L

Header_HC

Name

X

Y

Z

Parent

EA

EB

EG

HC

HC_Sprocket_L

-2900

0

0

HC_Initial_L

89

0

-90

Header_HC

Name

X

Y

Z

Parent

HC

HC_Idler_L

-700

0

0

HC_Initial_L

HC

HC_Wheel_1_L

-2460

-250

0

HC_Initial_L

HC

HC_Wheel_2_L

-2220

-250

0

HC_Initial_L

HC

HC_Wheel_3_L

-1930

-250

0

HC_Initial_L

HC

HC_Wheel_4_L

-1640

-250

0

HC_Initial_L

HC

HC_Wheel_5_L

-1350

-250

0

HC_Initial_L

HC

HC_Wheel_6_L

-1110

-250

0

HC_Initial_L

HC

HC_Carrier_Roller_1_L

-1780

360

0

HC_Initial_L

HC

HC_Tensioner_L

0

0

0

HC_Initial_L

HC

HC_Frame_L

0

0

0

HC_Initial_L

HC

HC_Frame_Fixed_L

-1780

0

0

HC_Initial_L

HC

HC_Tensioner_Fixed_L

-1200

0

0

HC_Initial_L

Now, Track_HC Sheet is completed.

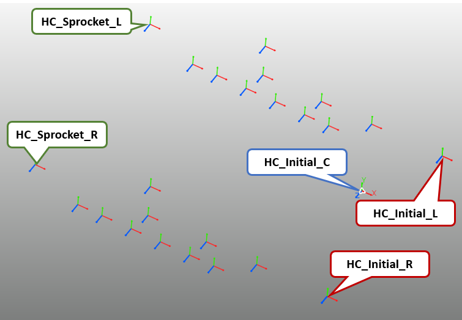

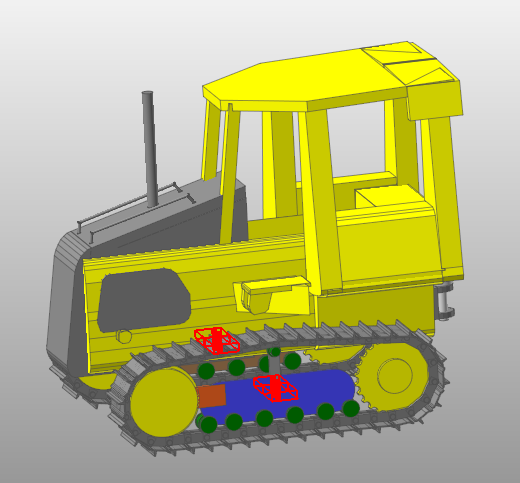

Save the Excel file and import it into RecurDyn. How to import eTemplate file is explained in chapter 9.

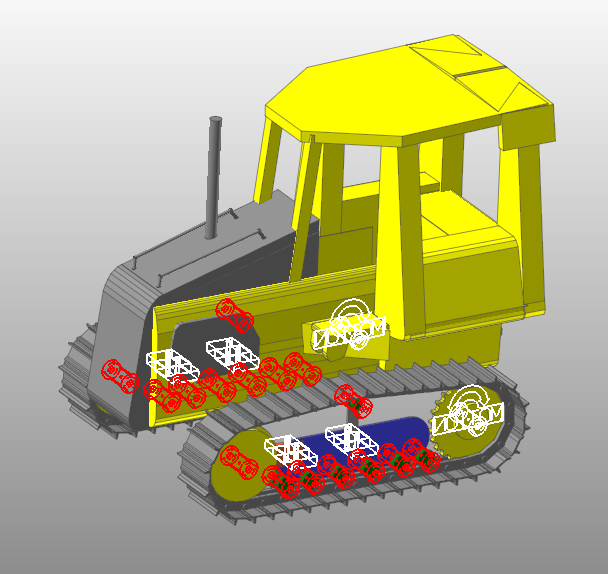

The below image shows the result when you import the eTemplate file.

11.2.5. Creating Bodies

11.2.5.1. Task Objective

In this chapter, you will learn how to import CAD files and create track bodies

11.2.5.2. Estimated Time to Complete

10 minutes

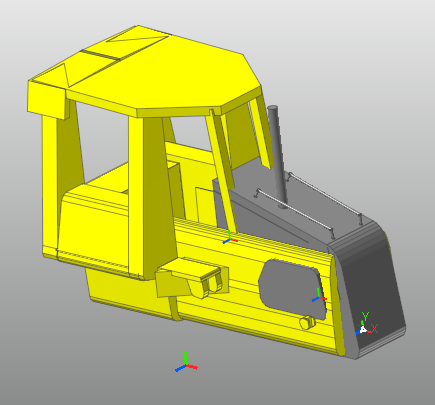

11.2.5.3. Creating Chassis Bodies

Please select Track_Body Sheet.

- Input the below information to import Chassis.x_t.(The file path: <InstallDir>\Help\Tutorial\Toolkit\eTemplate\CreationMode\Track_LM)

Header_Body_Import

Name

RefFrame

FileName

UseAutoMerge

Body_Import

Chassis

HC_Initial_C

Chassis.x_t

True

There are 2 options for Import. UseAutoMerge is the option to decide if you want to merge the imported files automatically. | Another option, which is not used in this tutorial is FilePath, | which is used when the CAD file exists in the different path from the path where eTemplate File (Excel file) is located.

You can use absolute coordinate input or relative coordinate input for RefFrame. You will use the relative coordinate input using HC_Initial_C which you created in the previous chapter. It means that Chassis uses the marker HC_Initial_C as a reference frame.

Tip

Absolute coordinate input vs. Relative coordinate inputAbsolute coordinate input uses numbers and commas directly. (e.g. 100, 200,300) relative coordinate input uses the existing marker name (ex : HC_Initial_C )

11.2.5.4. Creating Right-side Undercarriage

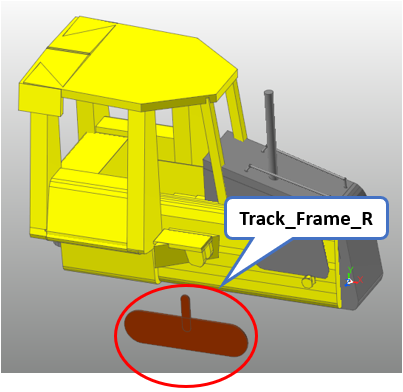

11.2.5.4.1. To create a track frame:

You will create a track frame where the track bodies will be fixed.

- Import Track_Frame.x_t.(The file path: <InstallDir>\Help\Tutorial\Toolkit\eTemplate\CreationMode\Track_LM)

Input HC_Frame_R for RefFrame to make the track frame on the right side. (Refer to Track_HC Data Tree in chapter 4)

Header_Body_Import

Name

RefFrame

FileName

UseAutoMerge

Body_Import

Track_Frame_R

HC_Frame_R

Track_Frame.x_t

True

Save the Excel file and import it into RecurDyn then the below model is created.

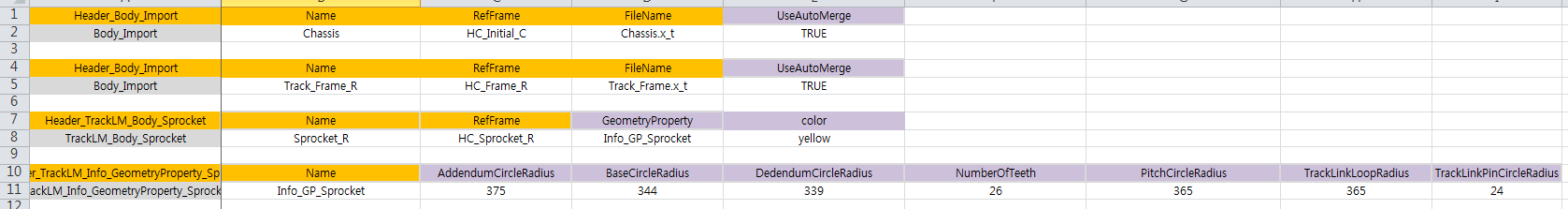

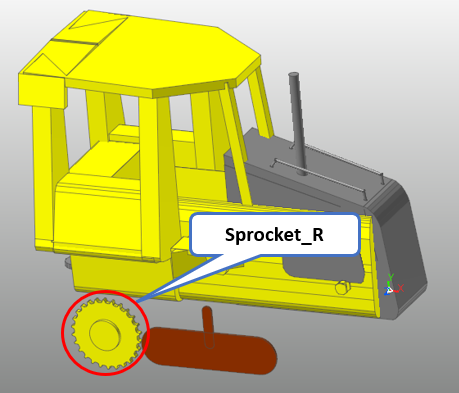

11.2.5.4.2. To create a sprocket:

You will create a sprocket, one of the track bodies.

Header_TrackLM_Body_Sprocket

Name

RefFrame

GeometryProperty

color

TrackLM_Body_Sprocket

Sprocket_R

HC_Sprocket_R

Info_GP_Sprocket

yellow

2 options, GeometryProperty and color are used here. If options are not input, RecurDyn uses the default values.

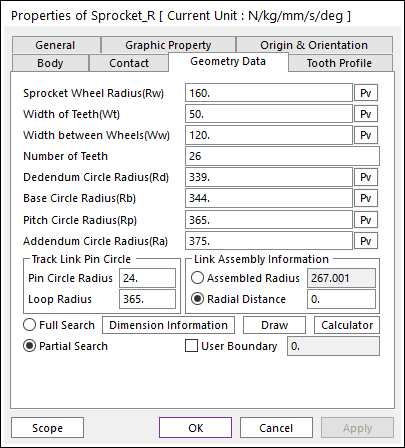

To use GeometryProperty, you need to create an Information for it. Input Info_GP_Sprocket for GeometryProperty. You will create an Information, whose name is Info_GP_Sprocket below.

Input yellow for color.

To create an Information, Info_GP_Sprocket for GeometryProperty, please input as below.

Header_TrackLM_Info_GeometryProperty_Sprocket

Name

AddendumCircleRadius

BaseCircleRadius

TrackLM_Info_GeometryProperty_Sprocket

Info_GP_Sprocket

375

344

DedendumCircleRadius

NumberOfTeeth

PitchCircleRadius

TrackLinkLoopRadius

TrackLinkPinCircleRadius

339

26

365

365

24

The above data needs to be input in the same line as below.

Save the Excel file and import it into RecurDyn then the below model is created.

Tip

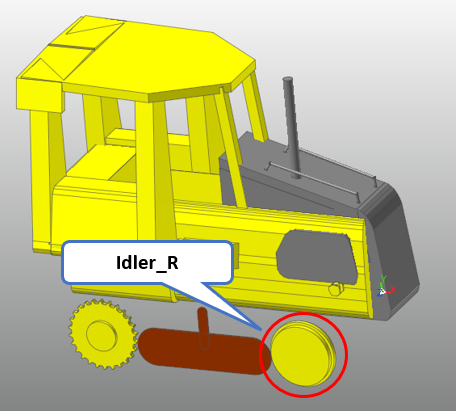

11.2.5.4.3. To create an idler:

You will create an idler, one of the track bodies.

Header_TrackLM_Body_FlangeCenter

Name

RefFrame

GeometryProperty

color

TrackLM_Body_FlangeCenter

Idler_R

HC_Idler_R

Info_GP_Idler

yellow

2 options, GeometryProperty and color are used here. If options are not input, RecurDyn uses the default values.

To use GeometryProperty, you need to create an Information for it. Input Info_GP_Idler for GeometryProperty. You will create an Information, whose name is Info_GP_Idler below.

To create an Information, Info_GP_Idler for GeometryProperty, please input as below.

Header_TrackLM_Info_GeometryProperty_FlangeCenter

Name

InnerFlangeRadius

WheelRadius

TrackLM_Info_GeometryProperty_FlangeCenter

Info_GP_Idler

350

320

Save the Excel file and import it into RecurDyn then the below model is created.

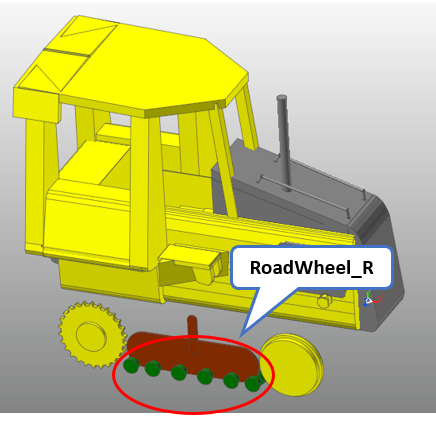

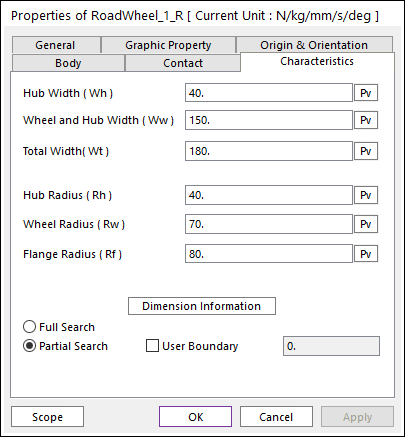

11.2.5.4.4. To create wheels:

You will create 6 wheels.

Header_TrackLM_Body_FlangeSingle

Name

RefFrame

GeometryProperty

color

TrackLM_Body_FlangeSingle

RoadWheel_1_R

HC_Wheel_1_R

Info_GP_Wheel

green

TrackLM_Body_FlangeSingle

RoadWheel_2_R

HC_Wheel_2_R

Info_GP_Wheel

green

TrackLM_Body_FlangeSingle

RoadWheel_3_R

HC_Wheel_3_R

Info_GP_Wheel

green

TrackLM_Body_FlangeSingle

RoadWheel_4_R

HC_Wheel_4_R

Info_GP_Wheel

green

TrackLM_Body_FlangeSingle

RoadWheel_5_R

HC_Wheel_5_R

Info_GP_Wheel

green

TrackLM_Body_FlangeSingle

RoadWheel_6_R

HC_Wheel_6_R

Info_GP_Wheel

green

To use GeometryProperty, you need to create an Information for it. Input Info_GP_Wheel for GeometryProperty. You will create an Information, whose name is Info_GP_Wheel below.

To create an Information, Info_GP_Wheel for GeometryProperty, please input as below.

Header_TrackLM_Info_GeometryProperty_FlangeSingle

Name

FlangeRadius

HubRadius

WheelRadius

TrackLM_Info_GeometryProperty_FlangeSingle

Info_GP_Wheel

80

40

70

Save the Excel file and import it into RecurDyn then the below model is created.

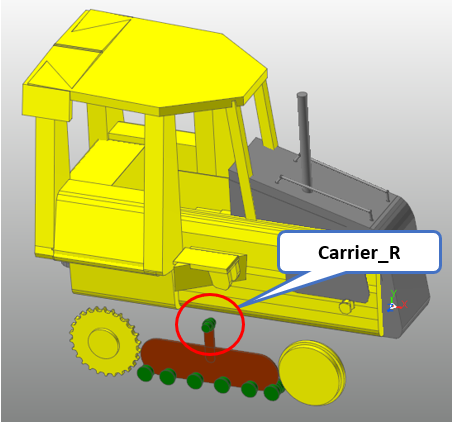

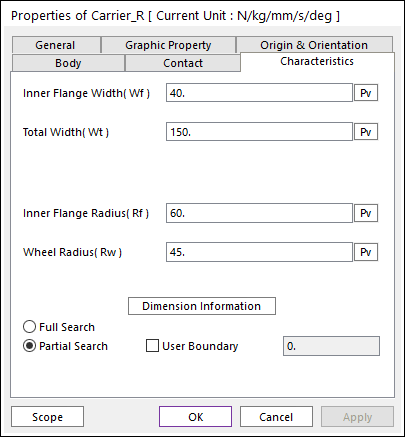

11.2.5.4.5. To create a carrier roller:

You will create a carrier roller, one of the track bodies.

Header_TrackLM_Body_FlangeCenter

Name

RefFrame

GeometryProperty

color

TrackLM_Body_FlangeCenter

Carrier_R

HC_Carrier_Roller_1_R

Info_GP_Carrier

green

To create an Information, Info_GP_Carrier for GeometryProperty, please input as below

Header_TrackLM_Info_GeometryProperty_FlangeCenter

Name

InnerFlangeRadius

WheelRadius

TrackLM_Info_GeometryProperty_FlangeCenter

Info_GP_Carrier

60

45

Save the Excel file and import it into RecurDyn then the below model is created.

11.2.5.4.6. To create a tensioner:

You will create a tensioner, one of the track bodies.

- Import Tensioner.x_t.(The file path: <InstallDir>\Help\Tutorial\Toolkit\eTemplate\CreationMode\Track_LM)

Header_Body_Import

Name

RefFrame

FileName

UseAutoMerge

Body_Import

Tensioner_R

HC_Tensioner_R

Tensioner.x_t

True

Save the Excel file and import it into RecurDyn then the below model is created.

11.2.5.5. Creating Left-side Undercarriage

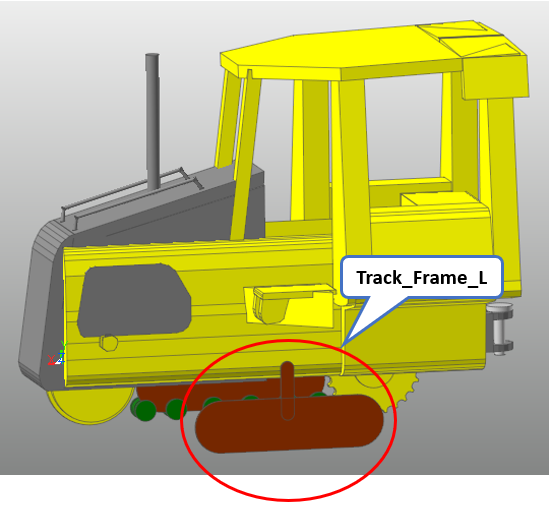

11.2.5.5.1. To create a track frame:

You will create a track frame where the track bodies will be fixed.

- Import Track_Frame.x_t.(The file path: <InstallDir>\Help\Tutorial\Toolkit\eTemplate\CreationMode\Track_LM)

Input HC_Frame_L for RefFrame to make the track frame on the left side. (Refer to Track_HC Data Tree in chapter 4)

Header_Body_Import

Name

RefFrame

FileName

UseAutoMerge

Body_Import

Track_Frame_L

HC_Frame_L

Track_Frame.x_t

True

Save the Excel file and import it into RecurDyn then the below model is created.

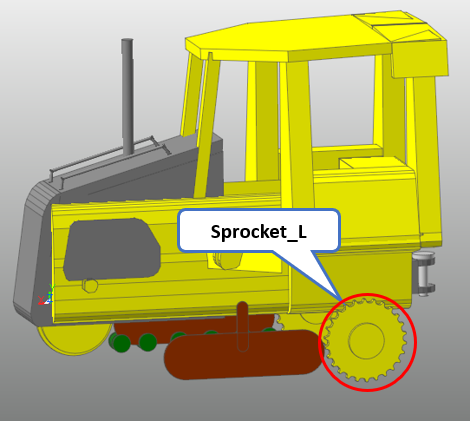

11.2.5.5.2. To create a sprocket:

You will create a sprocket, one of the track bodies.

Header_TrackLM_Body_Sprocket

Name

RefFrame

GeometryProperty

color

TrackLM_Body_Sprocket

Sprocket_L

HC_Sprocket_L

Info_GP_Sprocket

yellow

To use GeometryProperty, you need to create an Information for it. Input Info_GP_Sprocket for GeometryProperty. You already created Info_GP_Sprocket above so that you don’t need to create again.

The above data needs to be input in the same line as below.

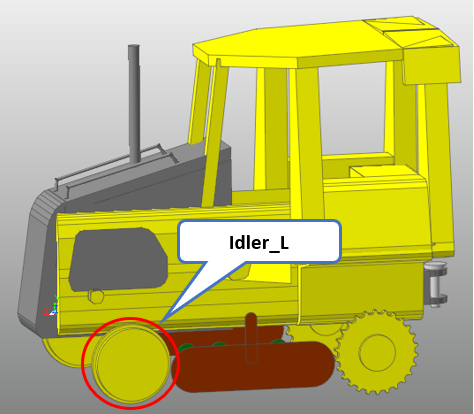

11.2.5.5.3. To create an idler:

You will create an idler, one of the track bodies.

Header_TrackLM_Body_FlangeCenter

Name

RefFrame

GeometryProperty

color

TrackLM_Body_FlangeCenter

Idler_L

HC_Idler_L

Info_GP_Idler

yellow

You already created Info_GP_Idler above so that you don’t need to create again.

Save the Excel file and import it into RecurDyn then the below model is created.

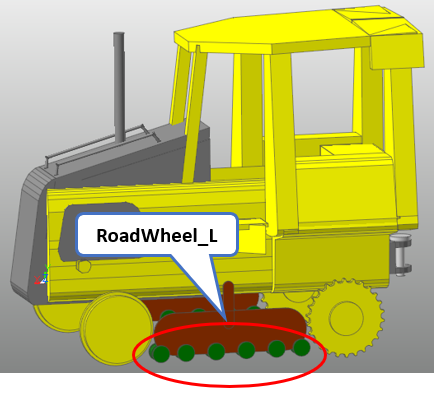

11.2.5.5.4. To create wheels:

You will create 6 wheels.

Header_TrackLM_Body_FlangeSingle

Name

RefFrame

GeometryProperty

color

TrackLM_Body_FlangeSingle

RoadWheel_1_L

HC_Wheel_1_L

Info_GP_Wheel

green

TrackLM_Body_FlangeSingle

RoadWheel_2_L

HC_Wheel_2_L

Info_GP_Wheel

green

TrackLM_Body_FlangeSingle

RoadWheel_3_L

HC_Wheel_3_L

Info_GP_Wheel

green

TrackLM_Body_FlangeSingle

RoadWheel_4_L

HC_Wheel_4_L

Info_GP_Wheel

green

TrackLM_Body_FlangeSingle

RoadWheel_5_L

HC_Wheel_5_L

Info_GP_Wheel

green

TrackLM_Body_FlangeSingle

RoadWheel_6_L

HC_Wheel_6_L

Info_GP_Wheel

green

You already created Info_GP_Wheel above so that you don’t need to create again.

Save the Excel file and import it into RecurDyn then the below model is created.

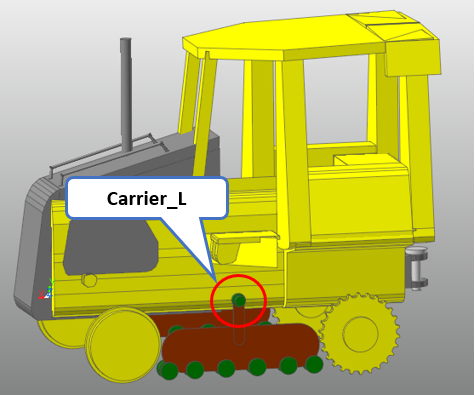

11.2.5.5.5. To create a carrier roller:

You will create a carrier roller, one of the track bodies.

Header_TrackLM_Body_FlangeCenter

Name

RefFrame

GeometryProperty

color

TrackLM_Body_FlangeCenter

Carrier_L

HC_Carrier_Roller_1_L

Info_GP_Carrier

green

You already created Info_GP_Carrier above so that you don’t need to create again.

Save the Excel file and import it into RecurDyn then the below model is created.

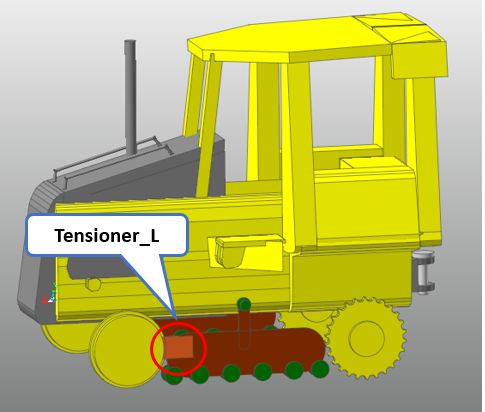

11.2.5.5.6. To create a tensioner:

You will create a tensioner, one of the track bodies.

- Import Tensioner.x_t.(The file path: <InstallDir>\Help\Tutorial\Toolkit\eTemplate\CreationMode\Track_LM)

Header_Body_Import

Name

RefFrame

FileName

UseAutoMerge

Body_Import

Tensioner_L

HC_Tensioner_L

Tensioner.x_t

True

Save the Excel file and import it into RecurDyn then the below model is created.

Now, you completed creating both of undercarriages.

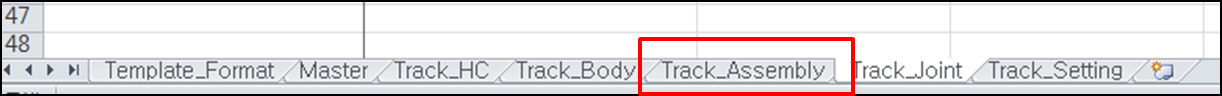

11.2.6. Creating Track Assembly

11.2.6.1. Task Objective

In this chapter, you will create a clone link and create track assembly using it.

11.2.6.2. Estimated Time to Complete

10 minutes

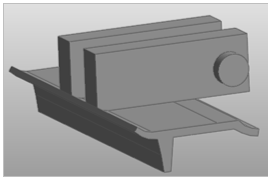

11.2.6.3. Creating Clone Link

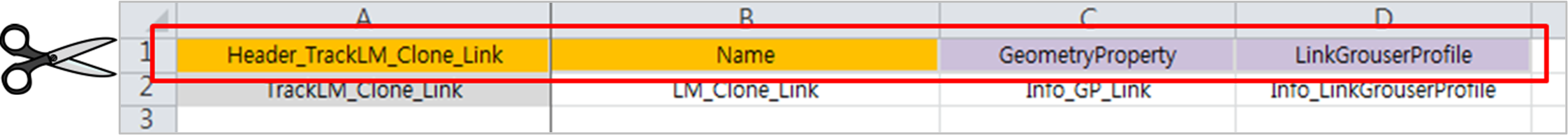

11.2.6.3.1. To create a clone link

Please select Track_Assembly Sheet.

Before creating track assembly, clone link needs to be created in advance.

Input the below information to create clone link.

Header_TrackLM_Clone_Link

Name

GeometryProperty

LinkGrouserProfile

TrackLM_Clone_Link

LM_Clone_Link

Info_GP_Link

Info_LinkGrouserProfile

2 options, GeometryProperty and LinkGrouserProfile are used here. If options are not input, RecurDyn uses the default values.

To create an Information, Info_GP_Link for GeometryProperty, please input as below.

PinRadius

RightLength

LeftPinPosition

RightPinPosition

24

119.5

-88.5,39

88.5,39

The above data needs to be input in the same line as below.

FileNameForGrouserProfile is the profile data to represent the shape of the grouser of a clonk link. You will import Grouser1.mat for it and this file must exist in the same path where the eTemplate file is located.

Header_TrackLM_Info_LinkGrouserProfile

Name

FileNameForGrouserProfile

TrackLM_Info_LinkGrouserProfile

Info_LinkGrouserProfile

Grouser1.mat

Save the Excel file and import it into RecurDyn then the below model is created.

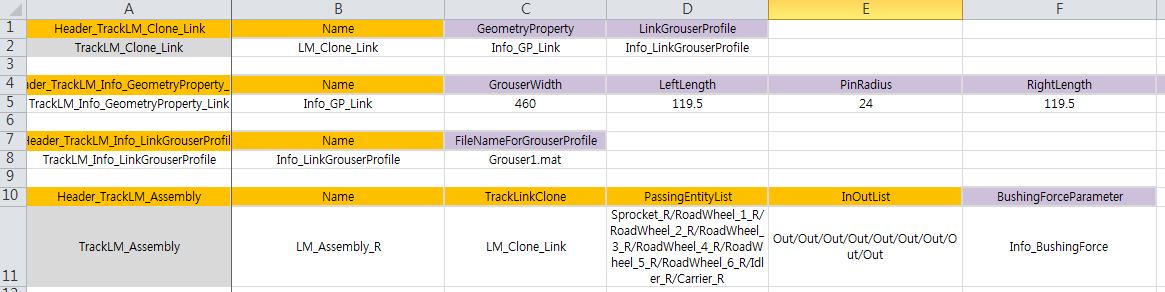

11.2.6.4. Creating Track Assembly

11.2.6.4.1. Creating Right-side Track Assembly

To create track assembly, the clone link which you just created before will be used.

Input the track bodies in order which consist of track assembly for the PassingEntityList. Input / between each track body.

Input PassingEntityList according to the below order.

Sprocket RoadWheel (1~6) Idler Carrier.

Header_TrackLM_Assembly

Name

TrackLinkClone

PassingEntityList

InOutList

TrackLM_Assembly

LM_Assembly_R

LM_Clone_Link

Sprocket_R/Road Wheel_1_R/Road Wheel_2_R/Road Wheel_3_R/Road Wheel_4_R/Road Wheel_5_R/Road Wheel_6_R/Idler_R/Carrier_R

Out/Out/Out/Out/Out/Out/Out/Out/Out

InOutList the parameter to decide if the track link is located inside or outside of Passing Entities. Please be careful that the number of the data of PassingEntityList must be same to the number of the InOutList data.

To create an Information, Info_BushingForce for BushingForceParameter, please input as below.

BushingForceParameter

Info_BushingForce

The data you input so far will look like as below

To use GeometryProperty, you need to create an Information for it. Input Info_BushingForce for BushingForceParameter. You will create an Information, whose name is Info_GP_Idler below.

Header_TrackLM_Info_Assembly_BushingForce

Name

RotationPresetAngle

TrackLM_Info_Assembly_BushingForce

Info_BushingForce

10

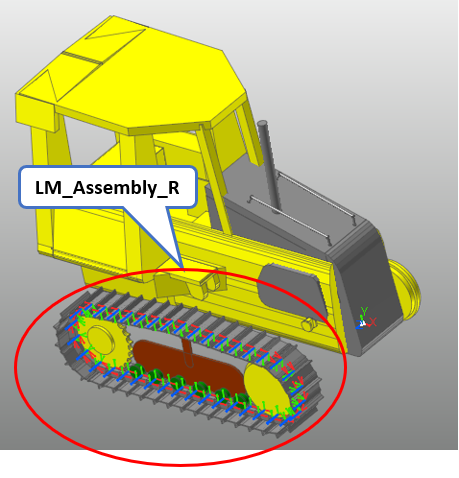

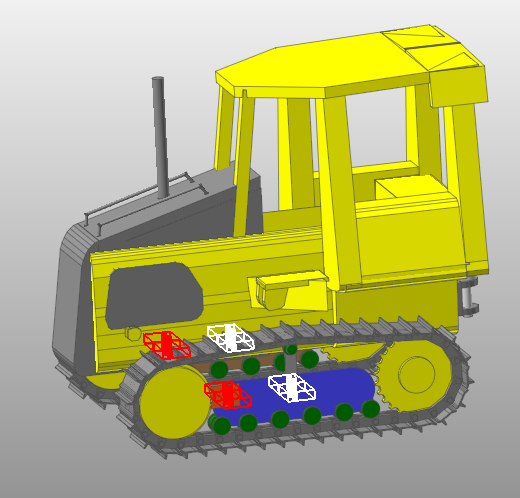

Save the Excel file and import it into RecurDyn then the below model is created.

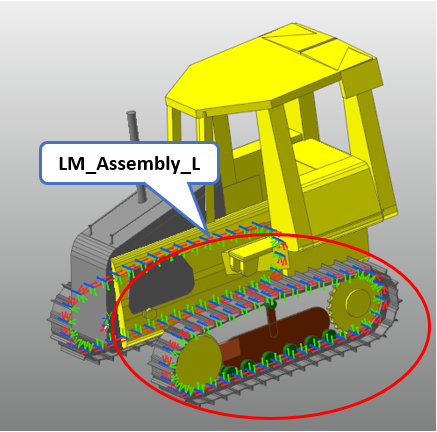

11.2.6.4.2. Creating Left-side Track Assembly

To create track assembly, the clone link which you just created before will be used.

Input the track bodies in order which consist of track assembly for the PassingEntityList. Input / between each track body. Please be careful that you need to input the track body names for left-side track assembly.

Header_TrackLM_Assembly

Name

TrackLinkClone

PassingEntityList

InOutList

TrackLM_Assembly

LM_Assembly_L

LM_Clone_Link

Sprocket_L/Road Wheel_1_L/Road Wheel_2_L/Road Wheel_3_L/Road Wheel_4_L/Road Wheel_5_L/Road Wheel_6_L/Idler_L/Carrier_L

Out/Out/Out/Out/Out/Out/Out/Out/Out

Please be careful that the number of the data of PassingEntityList must be same to the number of the InOutList data.

To use GeometryProperty, you need to create an Information for it. Input Info_BushingForce for BushingForceParameter. You will create an Information, whose name is Info_GP_Idler below.

You already created Info_BushingForce above so that you don’t need to create again.

BushingForceParameter

Info_BushingForce

Save the Excel file and import it into RecurDyn then the below model is created.

11.2.7. Creating Joints

11.2.7.1. Task Objective

In this chapter, you will learn how to create joints to connect the bodies you created. Also you will create a ground for simulation.

11.2.7.2. Estimated Time to Complete

10 minutes

11.2.7.3. Creating Fixed Joints

11.2.7.3.1. To create Fixed Joint between Chassis and Track Frame

Please select Track_Joint Sheet.

You will create 2 fixed joints to fix both Track Frames on Chassis.

Input Chassis for BaseEntity and Track_Frame_R and Track_Frame_L for ActionEntity.

Input HC_Frame_Fixed_R and HC_Frame_Fixed_L for each of RefFrame.

Header_JointEx_Fixed

Name

BaseEntity

ActionEntity

RefFrame

JointEx_Fixed

Fix_Track_Frame_R

Chassis

Track_Frame_R

HC_Frame_Fixed_R

JointEx_Fixed

Fix_Track_Frame_L

Chassis

Track_Frame_L

HC_Frame_Fixed_L

Save the Excel file and import it into RecurDyn then the below model is created.

You will create 2 fixed joints to connect both Tensioners on each Track Frame.

Input Track_Frame_R and Track_Frame_L for BaseEntity and Tensioner_R and Tensioner_L for ActionEntity.

Input HC_Tensioner_Fixed_R and HC_Tensioner_Fixed_R for each of RefFrame.

Header_JointEx_Fixed

Name

BaseEntity

ActionEntity

RefFrame

JointEx_Fixed

Fix_Tensioner_R

Track_Frame_R

Tensioner_R

HC_Tensioner_Fixed_R

JointEx_Fixed

Fix_Tensioner_L

Track_Frame_L

Tensioner_L

HC_Tensioner_Fixed_L

Save the Excel file and import it into RecurDyn then the below model is created.

11.2.7.4. Creating Revolute Joints

11.2.7.4.1. Revolute Joint creation and motion-defined

You will create 2 revolute joints to connect both sprockets on each Track Frame.

Input Track_Frame_R and Track_Frame_L for BaseEntity and Sprocket_R and Sprocket_L for ActionEntity.

Input HC_Sprocket_R and HC_Sprocket_R for each of RefFrame

Header_JointEx_Revolute

Name

BaseEntity

ActionEntity

RefFrame

JointEx_Revolute

Rev_Sprocket_R

Track_Frame_R

Sprocket_R

HC_Sprocket_R

JointEx_Revolute

Rev_Sprocket_L

Track_Frame_L

Sprocket_L

HC_Sprocket_L

Each of revolute joint has Motion, so that the below option needs to be input.

UseMotion

Motion

TRUE

Info_Joint_01

TRUE

Info_Joint_01

Since the motions use the option, you need to create an Information, whose name is Info_Joint_01 as below.

Firstly, you need to create an expression to be used for Motion either.

Header_SubEntity_Expression

Name

ExpressionText

SubEntity_Expression

Exp_Sprocket_Vel

-STEP(TIME, 0.1, 0, 1, 360D)

Create an Information whose name is Info_Joint_01 and input MotionType and MotionCondition as below.

Header_Info_JointMotion

Name

Expression

MotionType

MotionCondition

Info_JointMotion

Info_Joint_01

Exp_Sprocket_Vel

Standard

Velocity

Save the Excel file and import it into RecurDyn then the below model is created.

You will create 2 revolute joints to connect track bodies on each Track Frame.

11.2.7.4.2. To create Revolute Joint

Input as below to connect wheels and track frames for right-side undercarriage

Header_JointEx_Revolute

Name

BaseEntity

ActionEntity

RefFrame

JointEx_Revolute

Rev_Wheel_1_R

Track_Frame_R

RoadWheel_1_R

HC_Wheel_1_R

JointEx_Revolute

Rev_Wheel_2_R

Track_Frame_R

RoadWheel_2_R

HC_Wheel_2_R

JointEx_Revolute

Rev_Wheel_3_R

Track_Frame_R

RoadWheel_3_R

HC_Wheel_3_R

JointEx_Revolute

Rev_Wheel_4_R

Track_Frame_R

RoadWheel_4_R

HC_Wheel_4_R

JointEx_Revolute

Rev_Wheel_5_R

Track_Frame_R

RoadWheel_5_R

HC_Wheel_5_R

JointEx_Revolute

Rev_Wheel_6_R

Track_Frame_R

RoadWheel_6_R

HC_Wheel_6_R

Input as below to connect carrier to track frame.

Header_JointEx_Revolute

Name

BaseEntity

ActionEntity

RefFrame

JointEx_Revolute

Rev_FlangeCenter_1_R

Track_Frame_R

Carrier_R

HC_Carrier_Roller_1_R

Input as below to connect tensioner to idler.

Header_JointEx_Revolute

Name

BaseEntity

ActionEntity

RefFrame

JointEx_Revolute

Rev_Idler_R

Idler_R

Tensioner_R

HC_Idler_R

Input as below for left-side undercarriage either.

Header_JointEx_Revolute

Name

BaseEntity

ActionEntity

RefFrame

JointEx_Revolute

Rev_Wheel_1_L

Track_Frame_L

RoadWheel_1_L

HC_Wheel_1_L

JointEx_Revolute

Rev_Wheel_2_L

Track_Frame_L

RoadWheel_2_L

HC_Wheel_2_L

JointEx_Revolute

Rev_Wheel_3_L

Track_Frame_L

RoadWheel_3_L

HC_Wheel_3_L

JointEx_Revolute

Rev_Wheel_4_L

Track_Frame_L

RoadWheel_4_L

HC_Wheel_4_L

JointEx_Revolute

Rev_Wheel_5_L

Track_Frame_L

RoadWheel_5_L

HC_Wheel_5_L

JointEx_Revolute

Rev_Wheel_6_L

Track_Frame_L

RoadWheel_6_L

HC_Wheel_6_L

JointEx_Revolute

Rev_FlangeCenter_1_L

Track_Frame_L

Carrier_L

HC_Carrier_Roller_1_L

JointEx_Revolute

Rev_Idler_L

Idler_L

Tensioner_L

HC_Idler_L

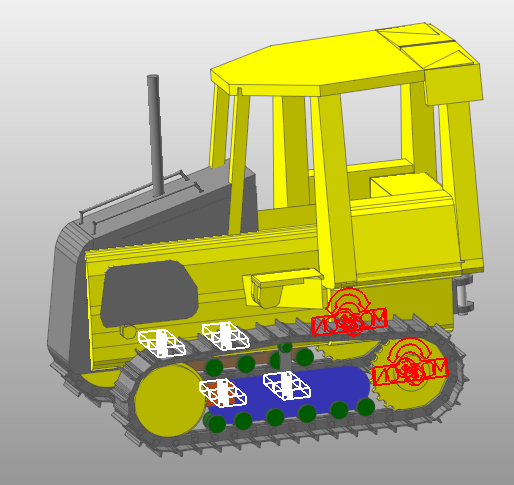

Save the Excel file and import it into RecurDyn then the below model is created.

Now, you completed creating track system.

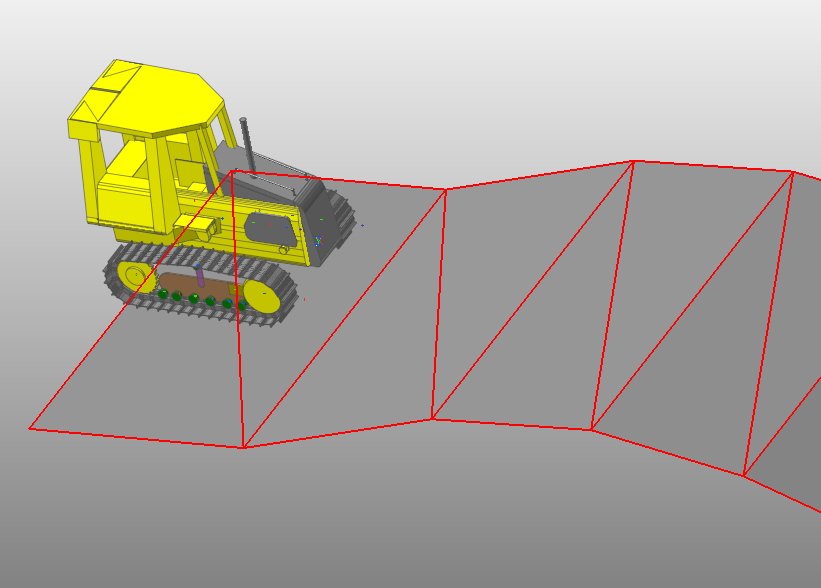

11.2.7.5. Creating Ground

In addition to the track system, you will import road where the track system will

You will Input the below information to import Terrain_Outline.rdf. This file must exist in the same path where the eTemplate file is located. If you want to use different road, you can use different rdf file.

Header_RoadData_Import

Name

FileName

RoadData_Import

Terrain_Outline

Terrain_Outline.rdf

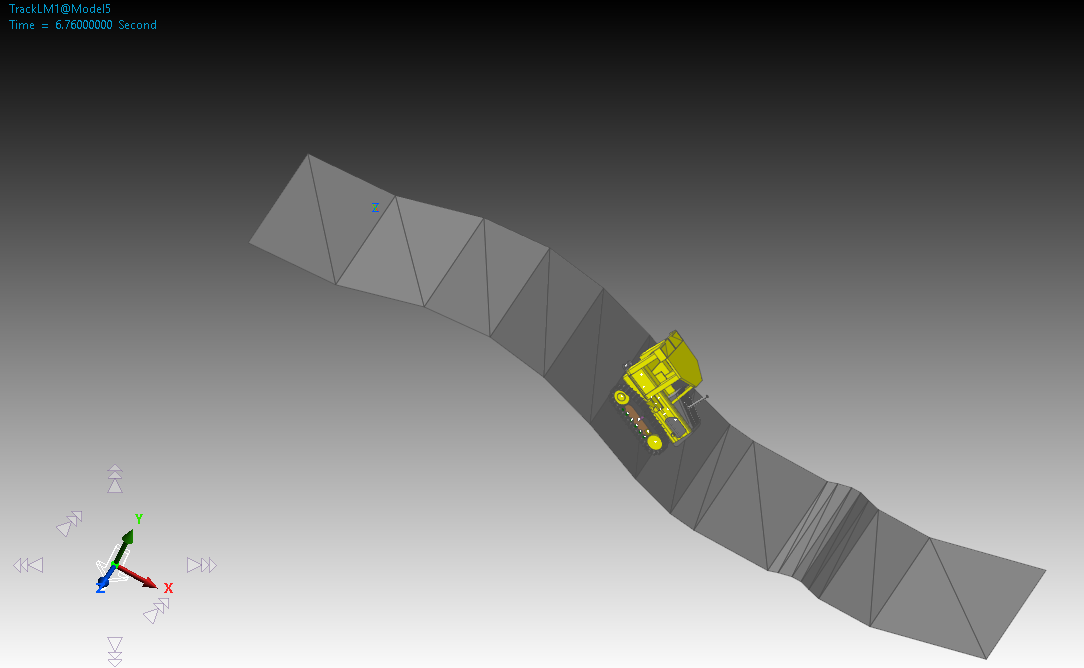

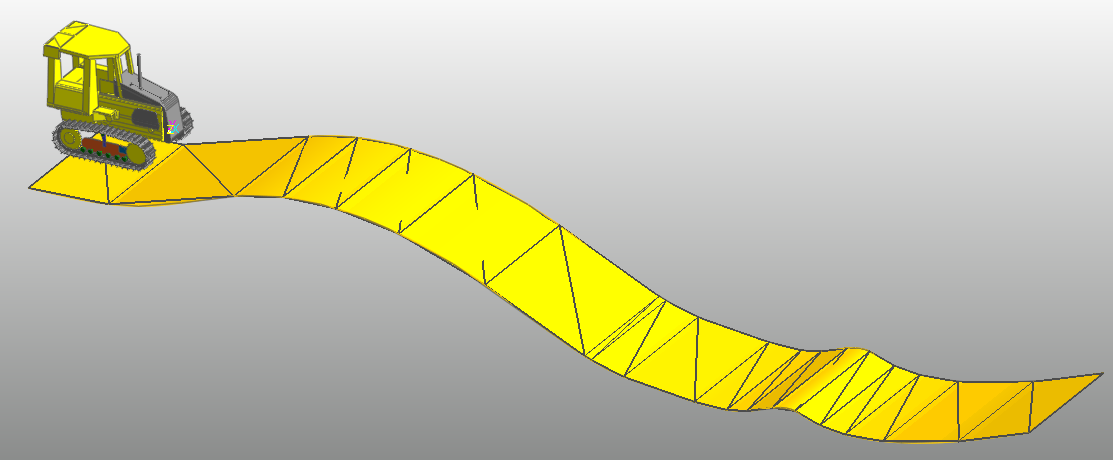

Save the Excel file and import it into RecurDyn then the below model is created.

11.2.8. Changing Settings

11.2.8.1. Task Objective

In this chapter, you will change some settings such as Dynamic Analysis Setting, Icon/Marker size and etc.

11.2.8.2. Estimated Time to Complete

10 minutes

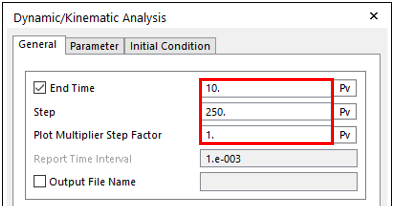

11.2.8.3. Changing Dynamic Analysis Settings

11.2.8.3.1. To change parameters for dynamic analysis:

Please select Track_Setting Sheet.

It is possible to change Simulation Time (End Time), Simulation Step (Step) and Plot Multiplier Step Factor using eTemplate.

Input as below.

Header_Setting_DynamicAnalysis

SimulationTime

SimulationStep

PlotMultiplierStepFactor

Setting_DynamicAnalysis

10

250

1

11.2.8.4. Changing Display Settings

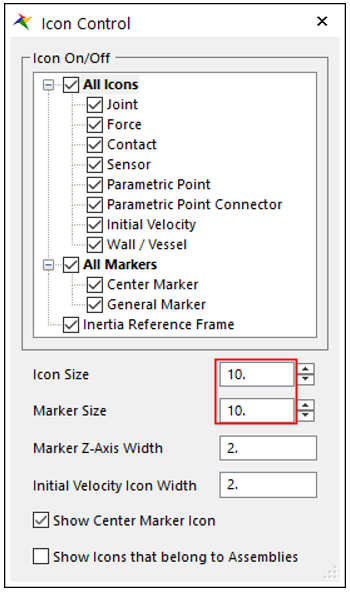

11.2.8.4.1. To change Icon/Marker size:

It is possible to change Icon/Marker size using eTemplate.

Input as below.

Header_Setting_Icon

IconSize

MarkerSize

Setting_Icon

10

10

The above settings are same to below.

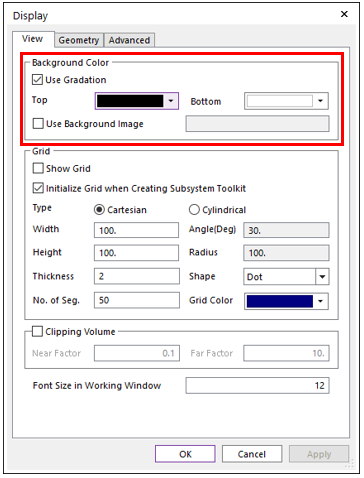

11.2.8.4.2. To change Background Color:

It is possible to change Background Color using eTemplate.

Input as below.

Header_Setting_BackGround

BottomColor

TopColor

UseGradation

Setting_BackGround

White

Black

TRUE

Please refer to the Appendix in the eTemplate manual for the color options you can use. Of course it is possible to input more colors using RecurDyn GUI.

11.2.9. Importing eTemplate File and Running Simulation

11.2.9.1. Task Objective

In this chapter, you will import the completed eTemplate file and run simulation.

11.2.9.2. Estimated Time to Complete

10 minutes

11.2.9.3. Importing eTemplate File

11.2.9.3.1. To import eTemplate file:

Launch RecurDyn

Input Track_LM_Tutorial for the name of the new model.

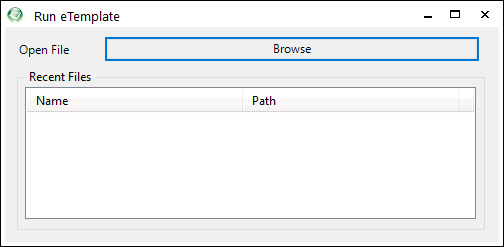

11.2.9.3.2. To executing eTemplate:

Since ModuleKey is set as Module_TrackLM, the eTemplate file can be imported only in Track_LM subsystem.

From the Subsystem Toolkit group of the Toolkit tab, click the Track(LM) function.

To execute eTemplate, from the eTemplate group of the Customize tab, click the Run function.

To import the eTemplate file (Excel file) created in the previous chapters, click Browse. The other files such as *.x_t, *.mat must exist in the same path with the eTemplate file.

11.2.9.4. Performing Analysis

11.2.9.4.1. To perform Analysis:

Click the Dynamic / Kinematic Analysis function in the Simulation Type group under the Analysis tab.

The Dynamic/Kinematic Analysis dialog box appears.

You can see that the parameters you changed in the previous chapter are applied.

Click Simulate.

Animate the model using the Play tool on the Animation Toolbar. Refer to TrackLM tutorial for more information on playing an animation.

Click the Stop tool to reset the model.