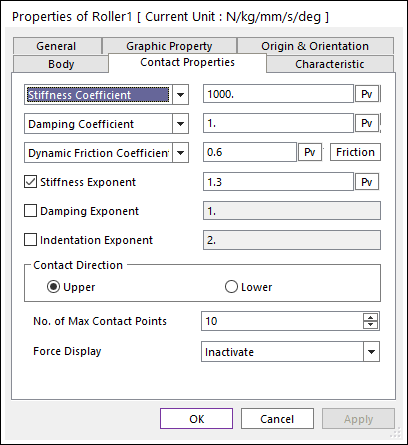

29.1.1. Contact Properties Page

This page defines characteristic values to contact between two geometry entities. Roller, Crown Roller, Flange, V-Pulley, Ribbed V-Pulley, and Timing Pulley supported in RecurDyn/Belt are using this page.

Figure 29.2 Roller property page [Contact Properties page]

Contact normal force

The contact normal force is obtained by

\(\mathbf{f}_\mathrm{n} = \mathbf{k}\delta^\mathrm{m1}+\mathbf{c}\frac{\dot{\delta}}{\left| \dot{\delta} \right|}\left| \dot{\delta} \right|^\mathrm{m2}\delta^\mathrm{m3}\)

where, \(\mathbf{k}\) and \(\mathbf{c}\) are the stiffness and damping coefficients which are determined by an experimental method, respectively. \(\delta\) and \(\dot{\delta}\) are a penetration and time differentiation of the penetration, respectively. The exponents \(\mathbf{m1}\) and \(\mathbf{m2}\) generates a non-linear contact force and the exponent \(\mathbf{m3}\) yields an indentation damping effect.

Characteristic: Defines the contact properties such as the stiffness coefficient, damping coefficient, and friction coefficients. Also, these coefficients can be given as user-defined spline curves.

Stiffness Coefficient: Specifies a stiffness coefficient for the contact normal force.

Stiffness Spline: The spline shows the contact normal force for the penetration. For more information, click here.

Damping Coefficient: Specifies a damping coefficient for the contact normal force.

Damping Spline: The spline shows the contact normal force for the velocity of penetration. For more information, click here.

Dynamic Friction Coefficient: Specifies a dynamic friction coefficient for the contact friction force. It has three options.

Dynamic Friction Coefficient: The constant friction coefficient is applied.

Friction Force Spline: The spline shows the fiction force for the relative velocity. It is recommended to use the spline that x and y values are defined as positive.

Friction Coefficient Spline: The spline shows the friction coefficient for the relative velocity.

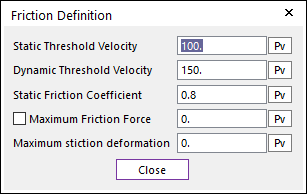

More: Specifies some friction coefficients for the contact friction force.

Stiffness and Damping Exponent: Generates a non-linear contact normal force.

Indentation Exponent: Yields an indentation damping effect. When the penetration is very small, the contact force may be negative due to a negative damping force, which is not realistic. This situation can be overcome by using the indentation exponent greater than one.

Contact Direction

Upper: If pulley and roller are contacted with the upper side of its belt, check this direction. The upper side means a +Y direction on its belt local orientation. Ex) The top surface of a timing belt (parameter type) is on a +Y direction, therefore this Upper is checked for the top surface to a pulley/roller contact case.

Lower: If pulley and roller are contacted with the lower side of its belt, check this direction. The lower side means a -Y direction on its belt local orientation. Ex) The tooth of a timing belt (parameter type) is on a -Y direction, therefore this Lower is checked for the tooth surface to a pulley/roller contact case.

No. of Max Contact Points : Defines the number of max contact point for output. User can define this value from 1 to 5000. This value only affects Force Display and RPLT data about the contact points. The default value is 10.

Force Display : Graphically displays the all contact force vectors (the sum of the normal and tangential contact force) at each contact point up to the No. of Max Contact Point.

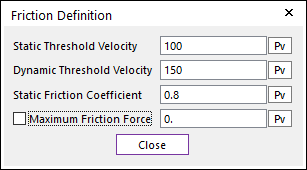

29.1.1.1. Friction

Friction defines the friction of Contact. And the user can also define the type as the following table.

Friction Type |

Entities |

Sliding and Stiction Type |

Element Assembly |

Sliding and Stiction Type |

2D Segment Assembly |

Sliding Type |

Segment Assembly |

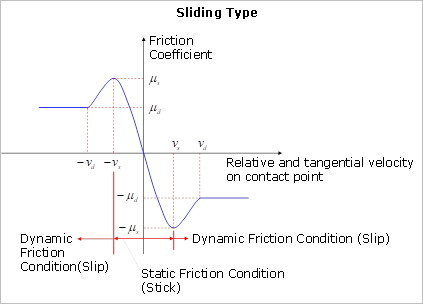

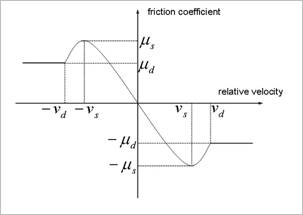

Sliding / Sliding & Stiction

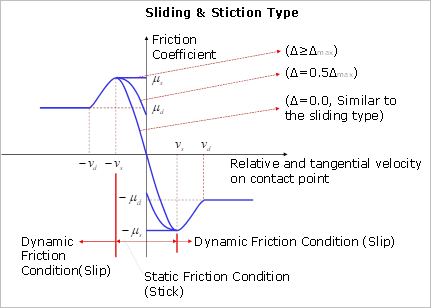

Friction type can be selected. The default value is sliding type. The difference between them is shown in Figure 29.3, Figure 29.4, and Table 29.2.

Figure 29.3 Sliding Type

Figure 29.4 Sliding & Stiction Type

Static Threshold Velocity (\({\nu }_{s}\)): This value is a criterion between static and dynamic friction. If the relative velocity is less than this value, the friction is on static friction. If not, the friction is on dynamic friction. The friction coefficient of static friction region is calculated from following equation for the sliding type. The mathematical definitions of all friction types are defined in Table 29.2.

\(\mu =\text{step5}\,(\nu ,\,\,0,\,\,0,\,\,{{\nu }_{s}},\,-\,{{\mu }_{s}}\,)\)

Dynamic Threshold Velocity (\({{v}_{d}}\)): If the relative velocity between a contact pair is greater than this value, the friction coefficient is same as the specified dynamic friction coefficient. If the relative velocity between a contact pair is greater than Static Threshold Velocity and less than this value, the friction coefficient is defined as following. The detail mathematical definitions is defined in Table 29.2.

\(\mu =\text{step5}\,(\nu ,\,\,{{\nu }_{s}},\,\,-{{\mu }_{s}},\,\,{{\nu }_{d}},\,\,-{{\mu }_{d}}\,)\)

Static Friction Coefficient (\({{\mu }_{s}}\)): Specifies a static friction coefficient.

Maximum Friction Force (\({{f}_{\max }}\)): If this is checked, the contact friction force is limited to this value.

Figure 29.5 Relationship between relative velocity and friction coefficient in the sliding friction type

The friction force of contact entities is determined by the following equations.

\({{f}_{f}}=-\,\text{sign}\,(v)\,\,\left| \mu (v) \right|\,\,\left| {{f}_{n}} \right|\)

\({{f}_{f}}=sign\,({{f}_{f}})\,\,\times \,\,\min \,(\,\left| {{f}_{f}} \right|,\,\,{{f}_{\max }}\,)\)

where, the \({{f}_{n}}\), \(\mu\) and \({{f}_{\max }}\) are the contact normal force, the friction coefficient and the maximum friction force, respectively. The friction coefficient of \(\mu (v)\) is determined by a relative and tangential velocity on the contact point.

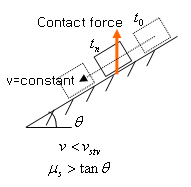

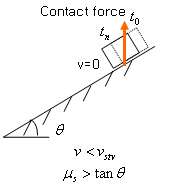

Table 29.2 Comparison in inclined plane model Type

Sliding

Sliding & Stiction

Static friction condition ( \(v\le {{v}_{s}}\) )

Mathematical definition for Static friction condition

\(\begin{aligned} & {{f}_{f}}={{\mu }_{v}}\left| {{f}_{n}} \right| \\ & {{\mu }_{v}}=\text{step5}(v,0.0,0.0,{{v}_{s}},-{{\mu }_{s}}) \\ \end{aligned}\)

\(\begin{aligned} & {{f}_{f}}=\{(1-{{\beta }_{v}}){{\mu }_{\Delta }}+{{\mu }_{v\_step5}}\}\left| {{f}_{n}} \right| \\ & {{\beta }_{v}}=\text{step5}(\left| v \right|,0.0,0.0,{{v}_{s}},1.0) \\ & {{\mu }_{\Delta }}=\text{step5}(\Delta ,0.0,0.0,{{\Delta }_{\max }},-{{\mu }_{s}}) \\ & {{\mu }_{v\_step5}}=\text{step5}(v,{{0.0}_{s}},0.0,{{v}_{s}},-{{\mu }_{s}}) \\ \end{aligned}\)

Note1)

In steady state, the slip is constant. Because, the friction force is function of relative and tangential velocity (\(v\))

In steady state, the slip is almost zero. Because, creep generate the stiction friction force for a stick effect.

Note2) Mathematical definition for Dynamic friction condition

\(\begin{aligned} & {{f}_{f}}=-\frac{v}{\left| v \right|}{{\mu }_{d}}\left| {{f}_{n}} \right| \\ & {{\mu }_{d}}=\text{step5}(\left| v \right|,{{v}_{s}},{{\mu }_{s}},{{v}_{d}},{{\mu }_{d}}) \\ \end{aligned}\)

\(\begin{aligned} & {{f}_{f}}=-\frac{v}{\left| v \right|}{{\mu }_{d}}\left| {{f}_{n}} \right| \\ & {{\mu }_{d}}=\text{step5}(\left| v \right|,{{v}_{s}},{{\mu }_{s}},{{v}_{d}},{{\mu }_{d}}) \\ \end{aligned}\)

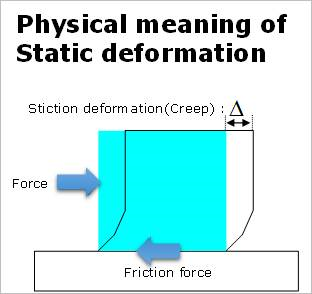

Maximum Stiction Deformation: This controls the stick-slip effect on the contact. The value must be greater than or equal to zero. If the tangential velocity is smaller than the static threshold velocity, then the stick effect can be occurred. On the other hand, if the tangential velocity is greater than the static threshold velocity, then the friction model is on the slip condition.

Note

The friction coefficient of Sliding & Stiction Type is function of relative velocity and creep (\(\Delta\)) while the friction coefficient of Sliding Type is function of relative velocity.