10.2.1.2. Generation of Input File

The user gets input files to make an rfi file following steps.

10.2.1.2.1. CMS Analysis (Mechanical APDL)

This section explains how to build FE model and analyze it with CMS method.

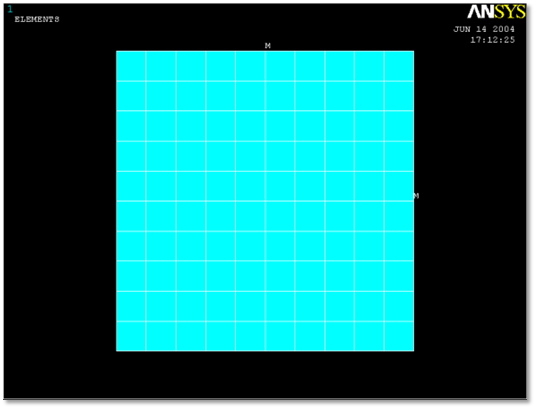

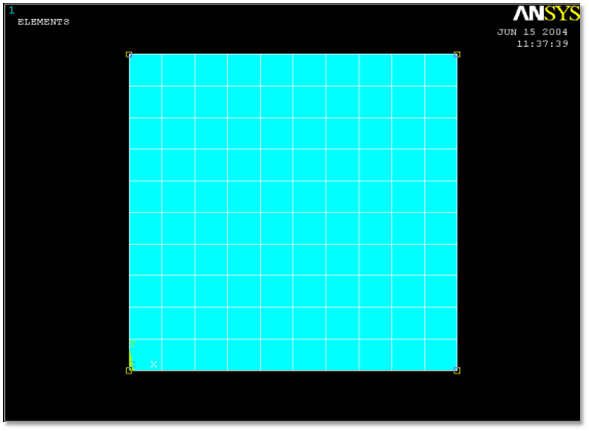

The example model is 2D rectangular model. The model can be meshed as shell 63 element with Element edge length option. Shell 63 elements have Real Constant with thickness, 0.05. Steel material is used in this model.

Figure 10.11 Target model

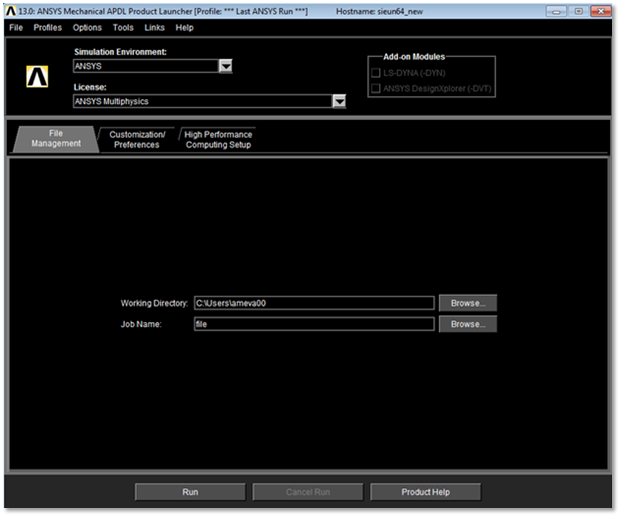

Select Mechanical APDL Product Launcher on the popup menu and specify working directory and job name.

Figure 10.12 ANSYS launcher

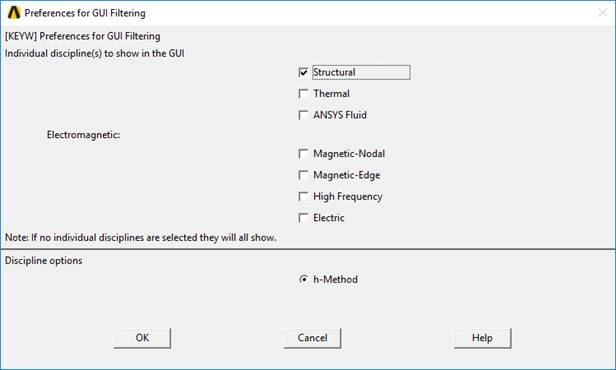

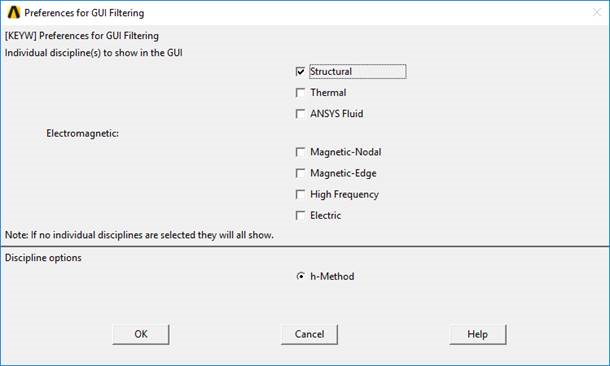

Select Structural on the Preferences for GUI filtering

Preferences for GUI filtering

Preferences > Structural

Figure 10.13 Preference for GUI filtering

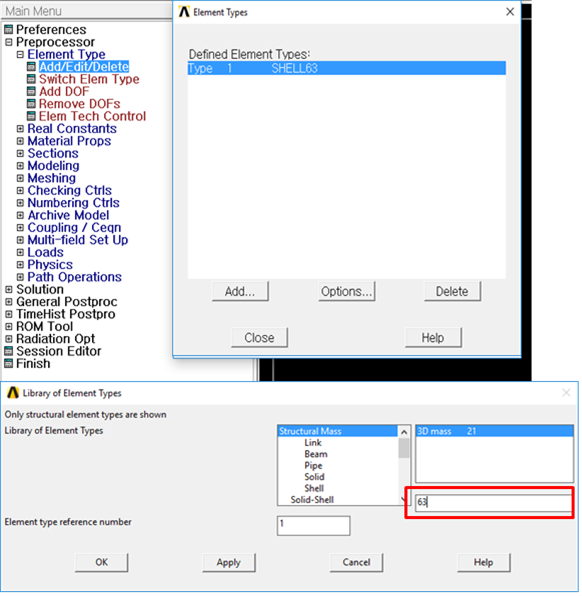

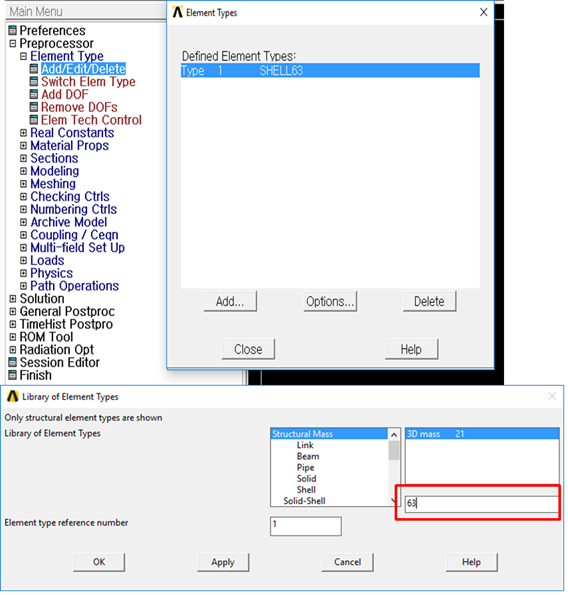

Select Element Type, Real Constants

Element type

Preprocessor > Element Type > Add/Edit/Delete > Add… > Shell 63 > OK > Close

Figure 10.14 Set Element Type

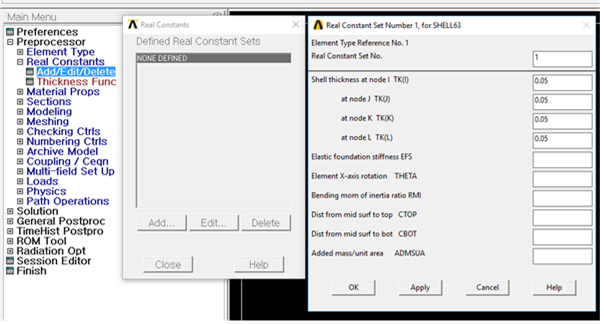

Enter Real Constants

Preprocessor > Real Constants > Add/Edit/Delete > Add > OK

Set shell thicknesses I, J, K, L as 0.05

Figure 10.15 Real constant for shell element

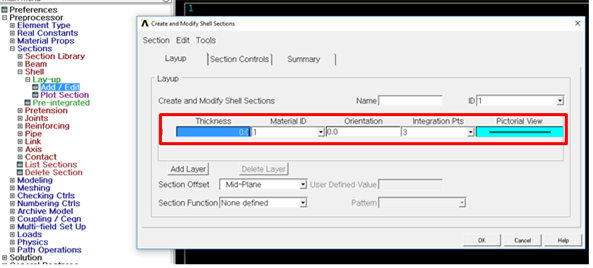

Thickness

- Thickness is important parameter for shell element. Ansys do not support Real Constant for some shell element.At the time, thickness can be define using shell section.

Figure 10.16 Create Sections for Shell Element

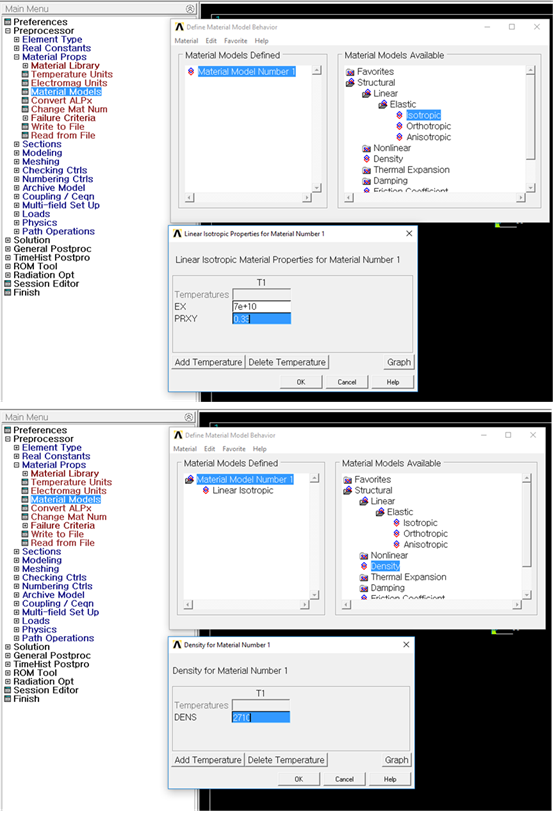

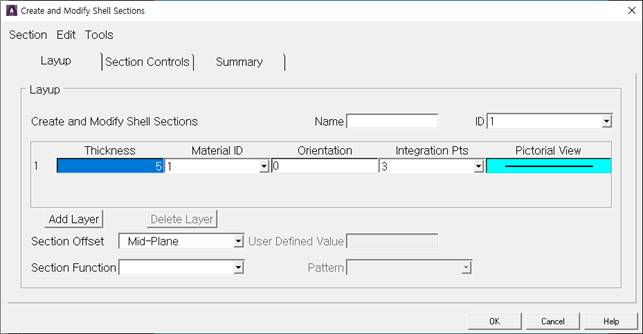

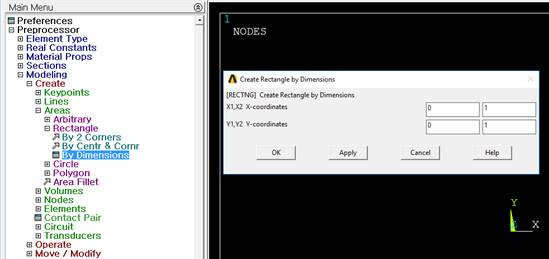

Enter Material property

Material property

Preprocessor > Material Props > Material Models > Structural > Linear > Elastic > Isotropic > Specify material number as 1 > OK

Fill in the Young’s modulus(70e9 \(N/m^2\)), Poisson’s ratio(0.33), density(2710 \(kg/m^3\)) > OK

Figure 10.17 Material Property

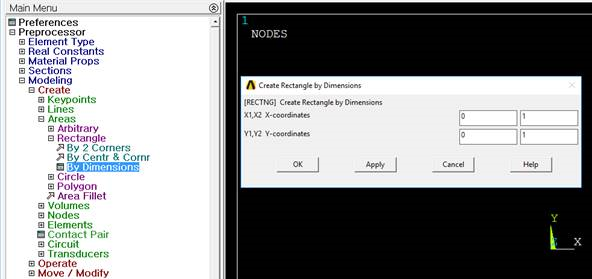

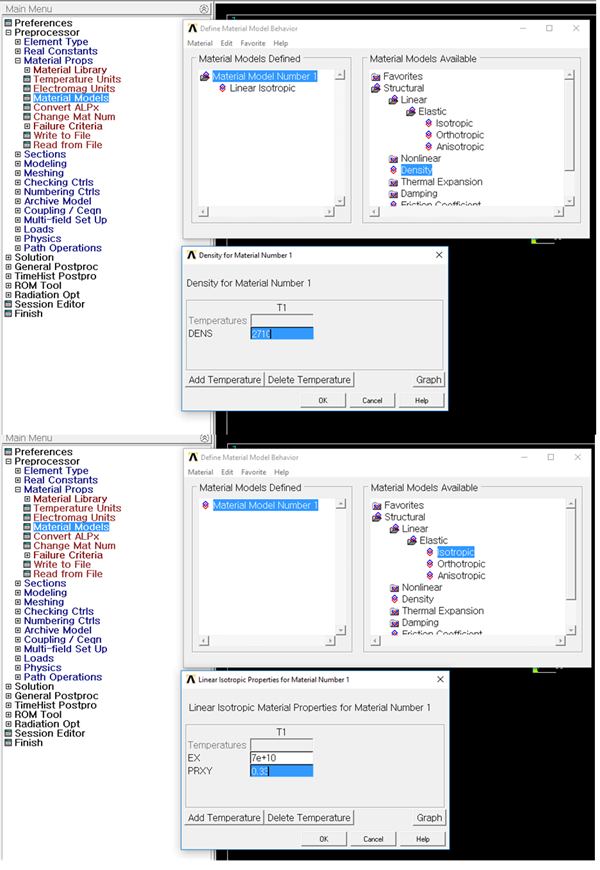

Create rectangular geometric entity

Create Rectangle by Dimensions

Preprocessor > Modeling > Create > Areas > Rectangle > By Dimensions > OK

Fill the x1, x2, y1, & y2 as 0.0, 0.0, 1.0, & 1.0 > OK

Figure 10.18 Rectangle by Dimensions

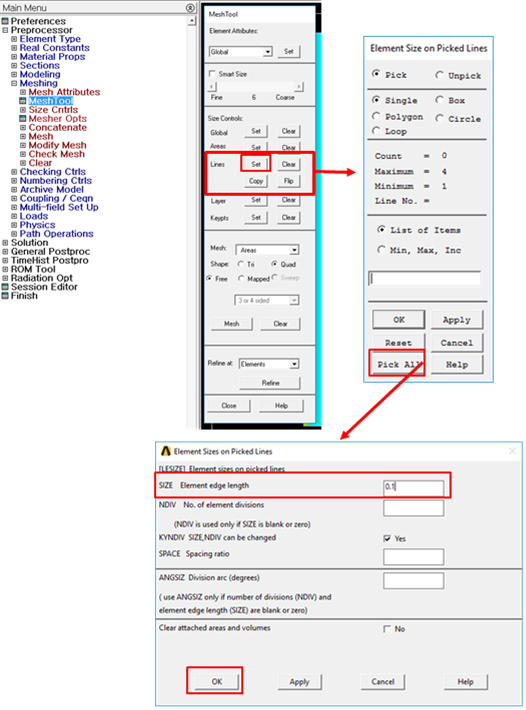

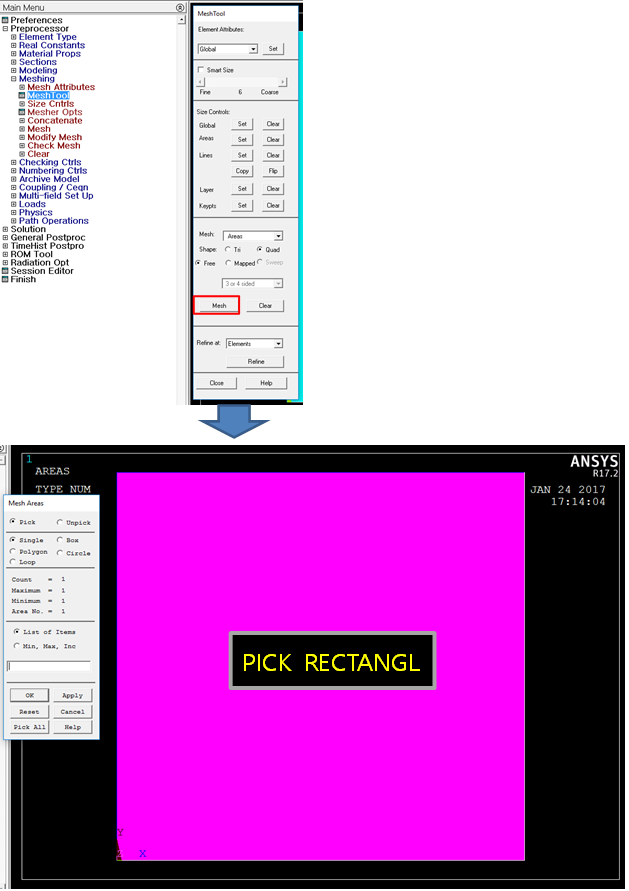

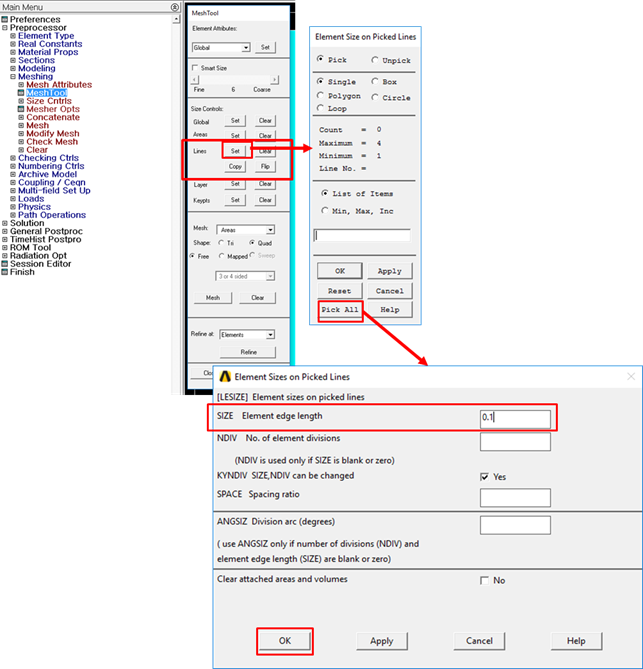

Create area meshing using Mesh Tools

Use line set to define element edge length.

Preprocessor > Meshing > MeshTool > Size Controls > Lines > Pick All > OK > SIZE element edge length(0.1) > OK

Figure 10.19 Line set with Element edge length

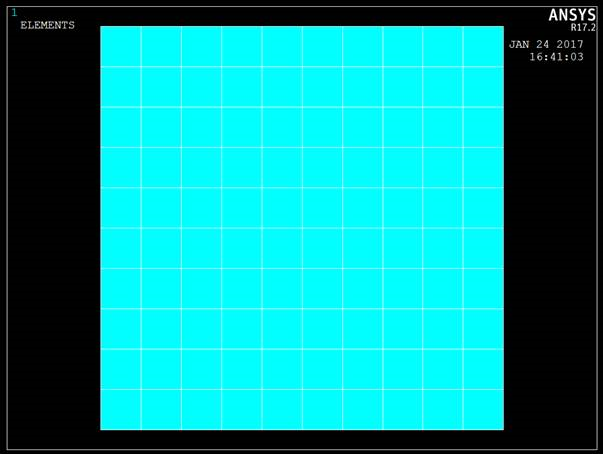

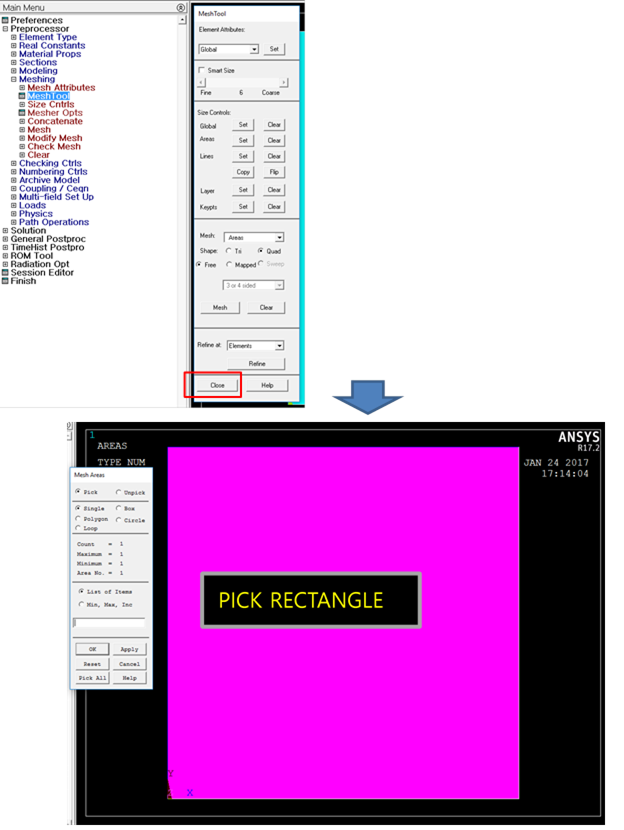

Mesh model

Mesh Tool > Mesh > Select model > OK

Figure 10.20 Meshed Rectangular geometric entity

Figure 10.21 Mesh Result

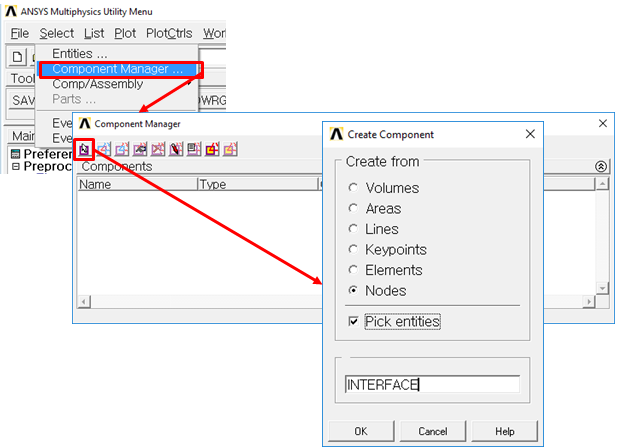

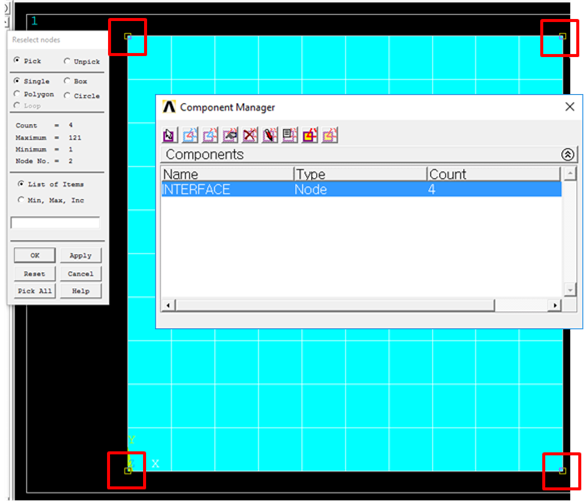

Define Interface nodes

Select> Component Manager

Create Component

Create from ‘Nodes’

Check ‘Pick entities’

Name new component ‘INTERFACE’

Select interface nodes on FE model

Figure 10.22 Create new component

Figure 10.23 Select Interface nodes

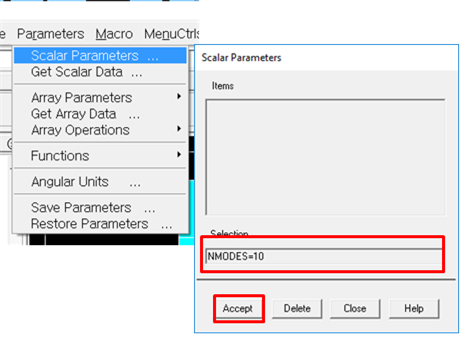

Define Parameter

Parameters> Scalar Parameters

Input the number of modes like ‘NMODES=10’

Accept it

Figure 10.24 Set the number of modes

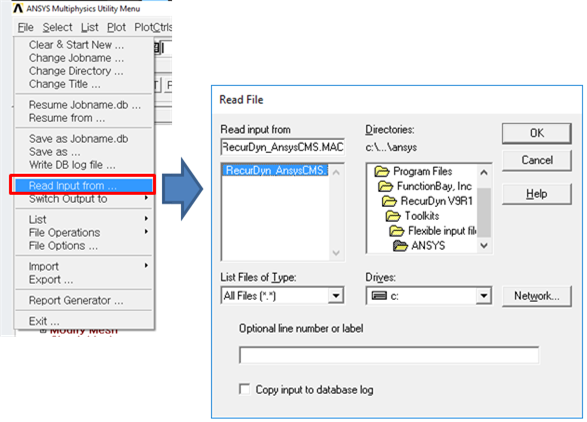

Read RecurDyn’s input file for CMS analysis

File> Read Input from

Read ‘RecurDyn_AnsysCMS.MAC’

This macro input file is included in the following folder.

‘<Install Dir>\Toolkits\Flexible input files\ANSYS’

Figure 10.25 Created files

Check the result files.

The four files must exist in work folder.

genCMS.rst

genCMS.mp

genCMS.emat

genCMS.cm

Caution

The user can perform the CMS(Component Mode Synthesis) analysis in ANSYS. CMS allows the user to derive the normal modes and static correction modes at once from ANSYS. It is difficult to perform CMS analysis by the provided steps of ANSYS. So, it is strongly recommended that the user performs CMS analysis with the provided macro file (RecurDyn_AnsysCMS.MAC). This macro file is included in <Install Dir>\Toolkits\Flexible input files\ANSYS\RecurDyn_AnsysCMS.MAC.

If ANSYS does not generate the element matrices file automatically, use the EMATWRITE command. If the user uses the macro file, this command is not needed.

If ANSYS does not generate the file included in material information automatically, the user should type the MPWRITE command in the solution menu. If the user uses the macro file, this command is not needed.

Note

The sample model is supported in <Install Dir>\Toolkits\Flexible input files\ANSYS directory.

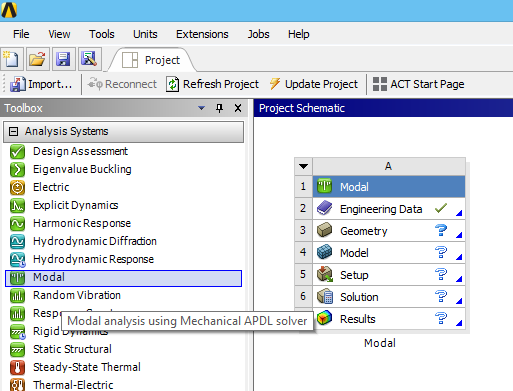

10.2.1.2.2. CMS Analysis (Workbench)

This section explains how to build FE model and analyze it with CMS method in Workbench.

The example model is 2D rectangular model.

Select Modal analysis in Analysis Systems.

Figure 10.26 Modal analysis system

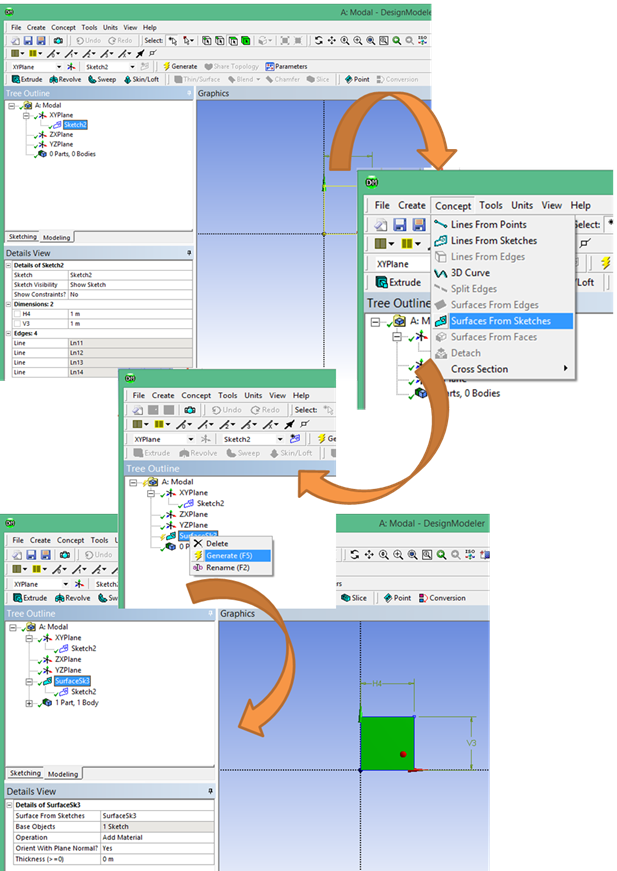

Create a geometry for FE model.

Enter DesignModeler program in the popup menu on Geometry.

Figure 10.27 Popup Menu on Geometry

Create a rectangle geometry in DesignModeler.

Activate Sketching Toolboxes by clicking Sketching page next to Modeling page. Create a 1m*1m rectangle on XY Plane by using Draw and Dimensions feature.

Create a surface from the sketch by using Surfaces From Sketches.

Generate the geometry by using Generate.

Figure 10.28 DesignModeler

Create a FE model and Analysis.

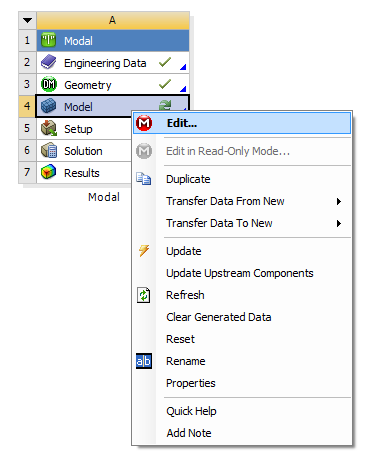

Enter Edit… on the popup menu on Model.

Figure 10.29 Popup Menu on Model

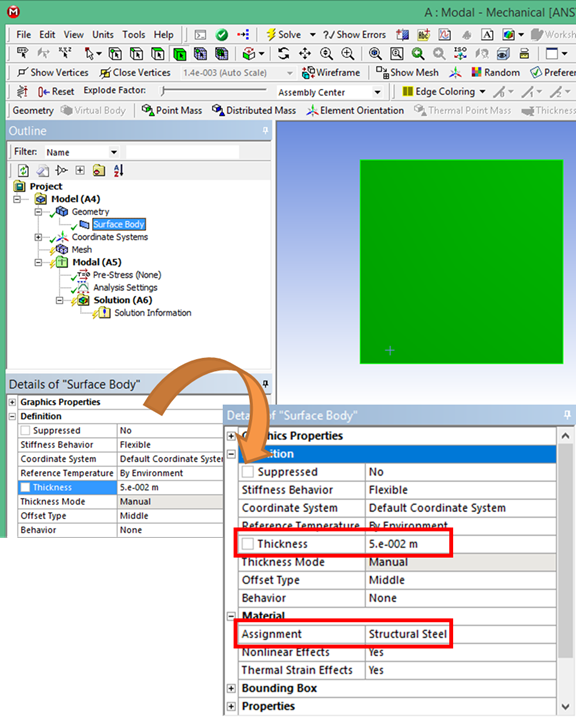

Define the thickness of the surface geometry as 0.05.

Define the material as Structural Steel.

Figure 10.30 Setting the thickness

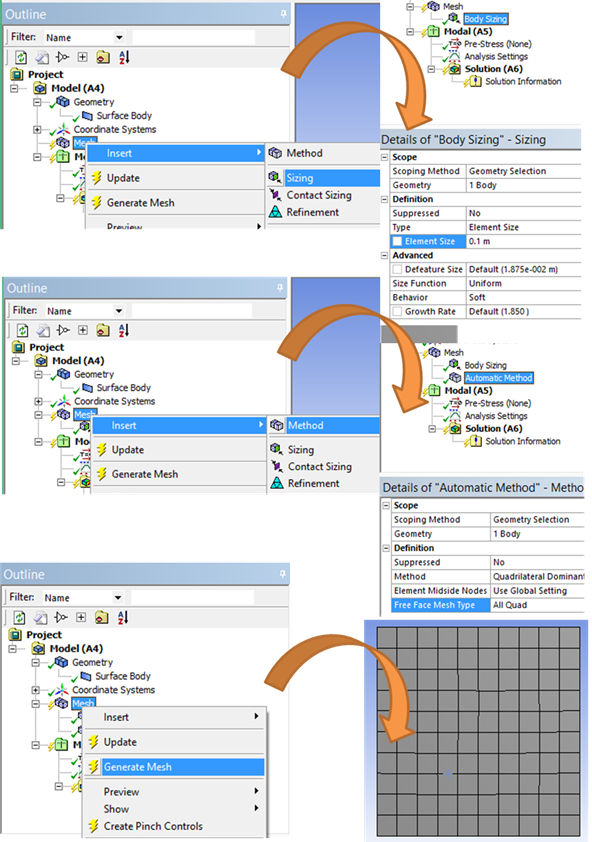

Mesh the surface geometry.

Set the element size as 0.1 by using Body Sizing.

Set the mesh type as all quad in Automatic Method.

Mesh with Generate Mesh.

Figure 10.31 Mesh the surface geometry

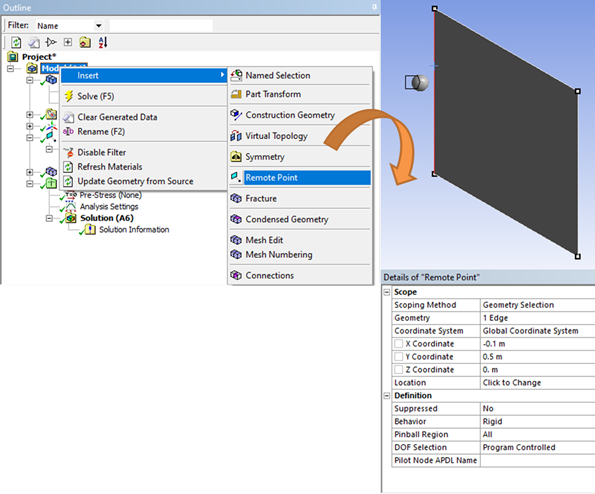

Define interface nodes.

Create a Remote Point to define interface nodes.

Set four vertices as Geometry

Set X, Y, and Z Coordinate as -0.1, 0.5, and 0.

Set Rigid Behavior in Definition

Figure 10.32 Setting Remote Point

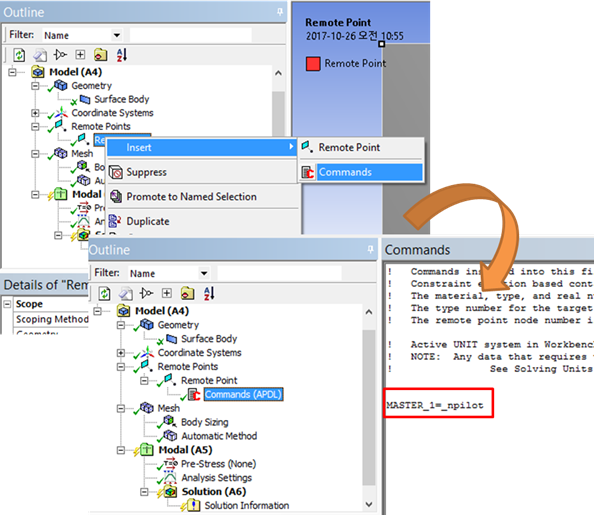

Insert a Command to define the name for the remote point.

“MASTER_1=_npilot”

Figure 10.33 Command for Remote Point

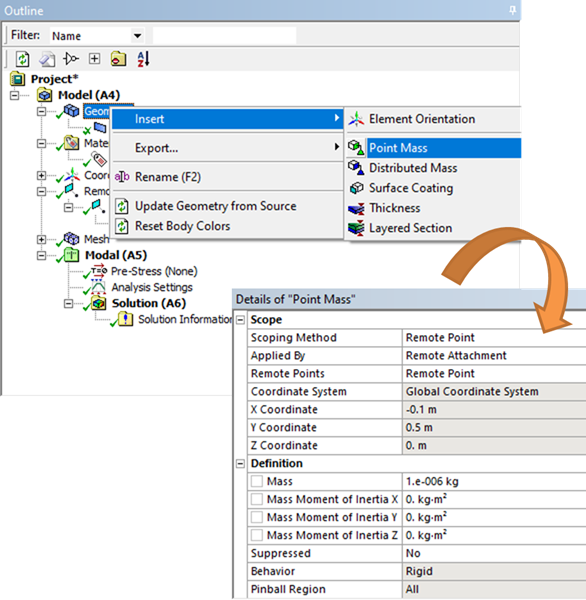

Create a Point Mass to define mass element.

Set Scoping Method as Remote Point.

Set Remote Points as the created Remote Point.

Set the mass as 1-e6 in Definition

Figure 10.34 Setting Point Mass

Solve Modal Analysis

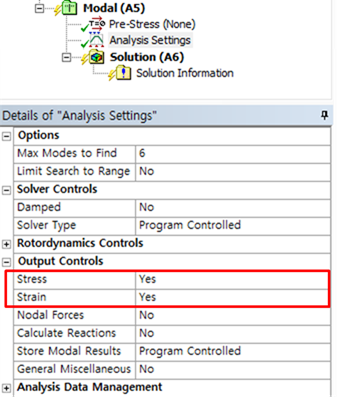

Define Analysis Settings

In order to include strain shape and stress shape, check Output Controls.

Figure 10.35 Analysis Settings

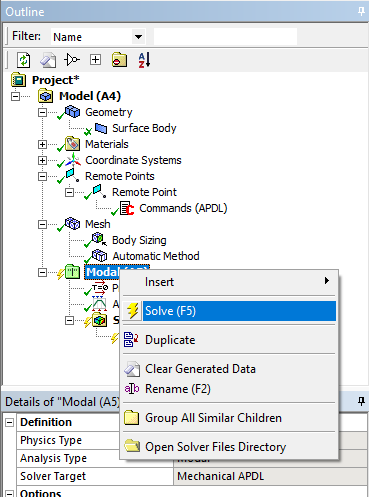

Solve

Figure 10.36 Performing Modal Analysis

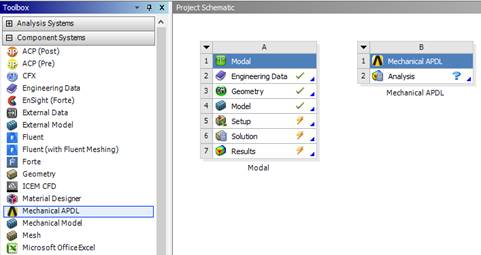

Select Mechanical APDL in Component Systems

Figure 10.37 Mechanical APDL in WorkBench

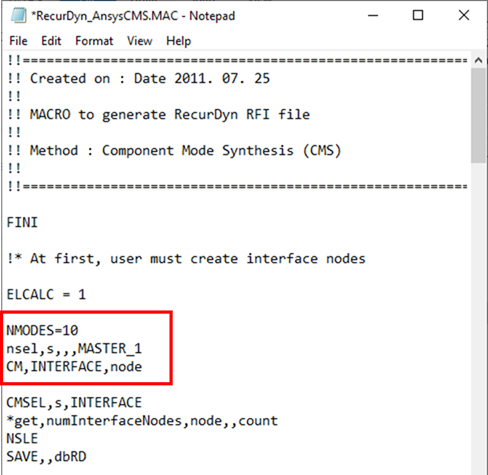

Create a MAC file.

Insert a command for CMS analysis.

Edit the macro input file contents provided by RecurDyn. The file is in <Install Dir>\Toolkits\Flexible input files\ANSYS folder.

NMODES and CM parameters should be inputted.

“NMODES=10”

“nsel,s,,,MASTER_1”

“CM,INTERFACE,node”

Save the modified file

Figure 10.38 Edited MAC file

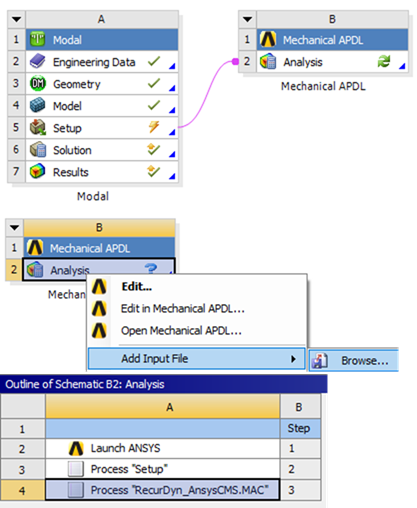

Solve CMS Analysis.

Assign Model setting

Add created MAC file

Figure 10.39 CMS Analysis setting

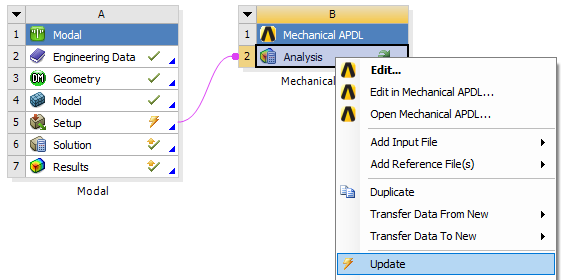

Solve

Figure 10.40 Performing CMS Analysis

Check the result files.

The file is in <ProjectFolder>dp0APDLANSYS

The four files must exist in this folder.

genCMS.rst

genCMS.mp

genCMS.emat

genCMS.cm

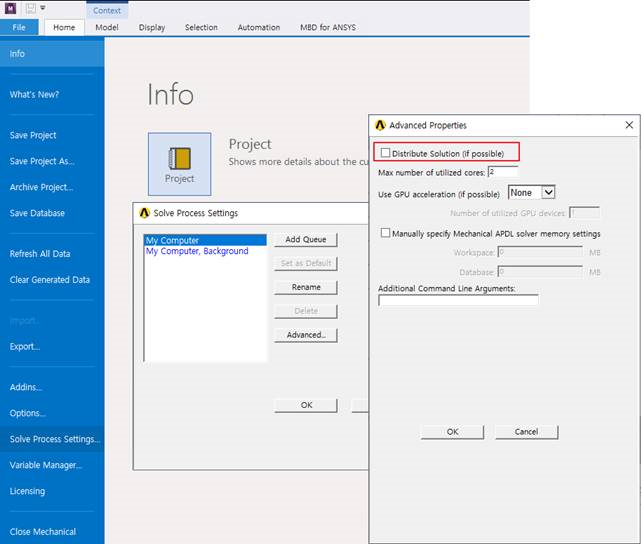

Note

For accurate analysis, Distribute Solution option should be turned off in Mechanical program.

10.2.1.2.3. Modal Analysis (Mechanical APDL)

The example model is 2D rectangular model. The model meshed based on shell 63 element with Element edge length option. Shell 63 element has Real Constant with thickness and the value are same as 0.05 for all. Furthermore, use material property like as steel and boundary condition to fix all degree of freedom impose at all left side node.

Figure 10.41 Target model

Select Mechanical APDL Product Launcher on the popup menu and specify working directory and job name.

Figure 10.42 Interactive dialog box

Select Structural on the Preferences for GUI filtering

Preferences for GUI filtering

Preferences > Structural

Figure 10.43 Preference for GUI filtering

Select Element Type, Real Constants

Element type

Preprocessor > Element Type > Add/Edit/Delete > Add… > Shell 63 > OK > Close

Enter Real Constants

Preprocessor > Real Constants > Add/Edit/Delete > Add > OK

Set shell thicknesses I, J, K, L as 0.05

Figure 10.44 Real constant for shell element

Thickness

- Thickness is important parameter for shell element. Ansys do not support Real Constant for some shell element.At the time, thickness can be define using shell section.

Figure 10.45 Create Sections for Shell Element

Enter Material property

Material property

Preprocessor > Material Props > Material Models > Structural > Linear > Elastic > Isotropic > Specify material number as 1 > OK

Fill in the Young’s modulus(70e9 \(N/m^2\)), Poisson’s ratio(0.33), density(2710 \(kg/m^3\)) > OK

Figure 10.46 Material Property

Create rectangular geometric entity

Create Rectangle by Dimensions

Preprocessor > Modeling > Create > Areas > Rectangle > By Dimensions > OK

Fill the x1, x2, y1, & y2 as 0.0, 0.0, 1.0, & 1.0 > OK

Figure 10.47 Rectangle by Dimensions

Create area meshing using Mesh Tools

Use line set to define element edge length.

Preprocessor > Meshing > MeshTool > Size Controls > Lines > Pick All > OK > SIZE element edge length(0.1) > OK

Figure 10.48 Line set with Element edge length

Mesh model

Mesh Tool > Mesh > Select model > OK

Figure 10.49 Meshed Rectangular geometric entity

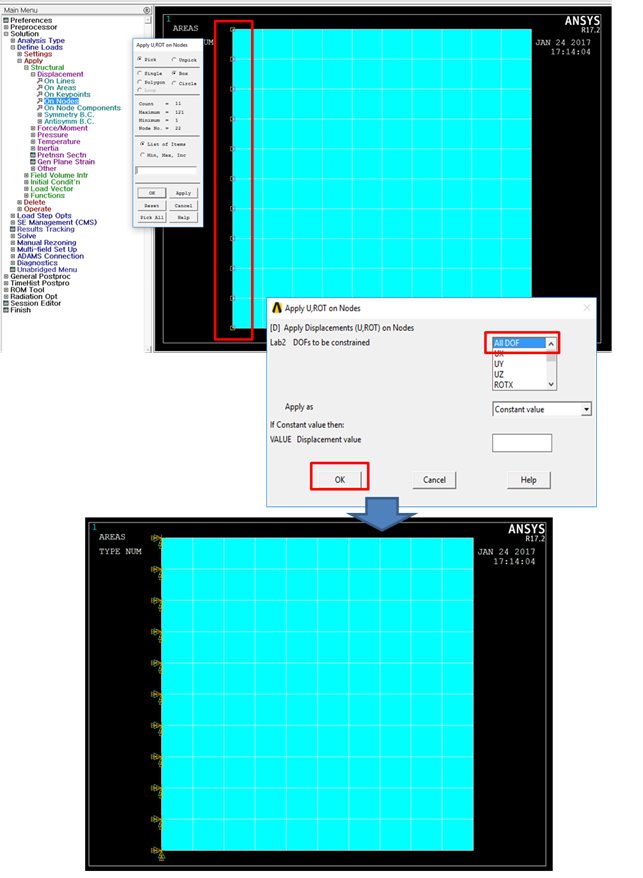

Impose Boundary Conditions on nodes

Apply at node

Fix all degree of freedom of left side node

Solution > Loads > Define Loads > Apply > Structural Displacement > On Nodes > Box > drag the window > OK > All DOF > OK

Figure 10.50 Boundary condition

Create output files

Create *.mp file

Ansys Command Prompt > ‘mpwrite’

Create *.emat file

Ansys Command Prompt > ematwrite, yes’

Perform modal analysis

Set Analysis Type

Solution > Analysis Type > New Analysis > Modal

Set Analysis Options

Solution > Analysis Type > Analysis Options

Determine the Number of modes to extract and check lumped mass option

You can also define Start and End frequency

Perform analysis

Solution > Solve > Current LS > Finish

Check created files

Created files were stored in working directory

file.rst

file.mp

file.emat