32.4. CCMAV (Torque Control of Constant Mean Angular Velocity of a Crank-Shaft)

CCMAV (Torque Control of Constant Mean Angular Velocity of a Crank-Shaft) allows getting the value of initial velocity and the value of the count torque for regularly keeping the angular velocity of a crank-shaft. The gas force is applied by the rotation angle of the crank-shaft, the crank-shaft is accelerated by the gas force. If the gas force is same because of the count torque applied by the engine, the crank-shaft is rotated by the regular speed. So, the value of the count torque is needed to apply the virtual system. CCMAV is a processor to decide the initial velocity of the crank-shaft and the count torque which gives the regular speed to the crank-shaft in the decided gas force through the repeated simulation by ProcessNet.

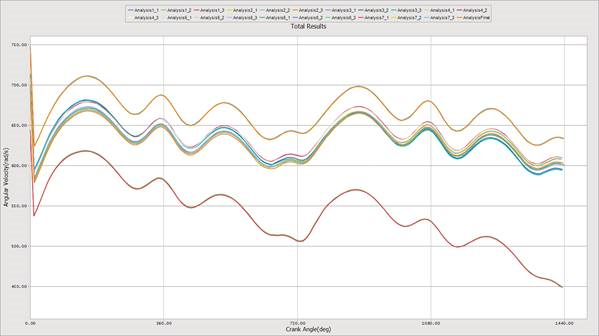

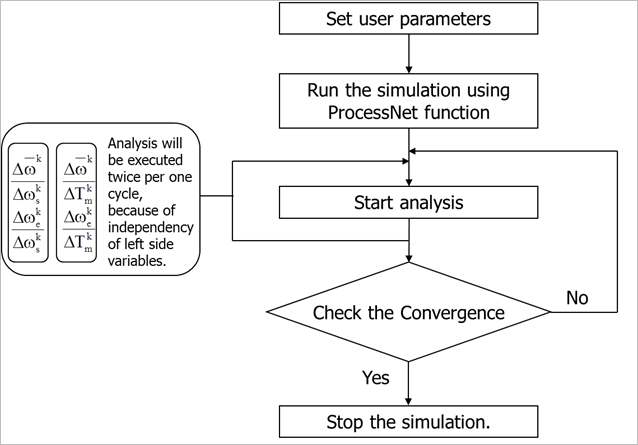

Figure 32.169 A process of control algorism for CCMAV

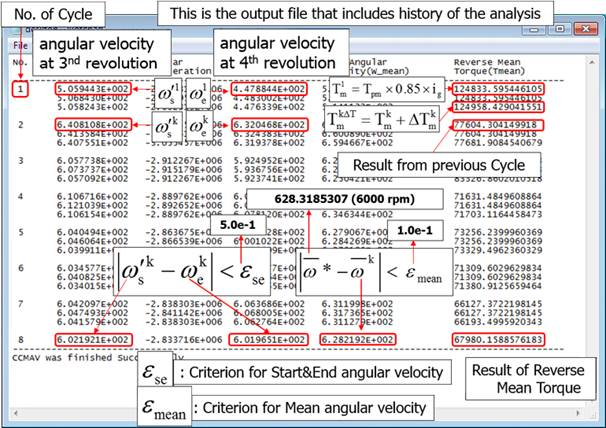

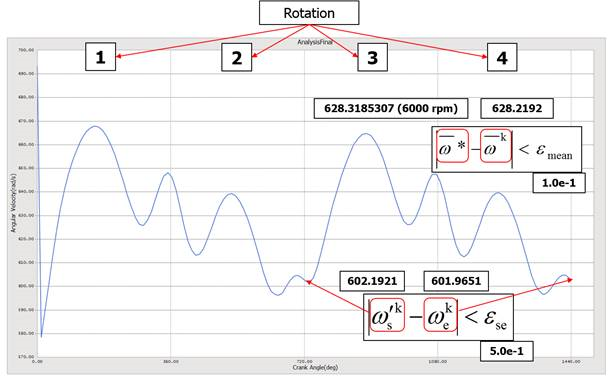

\(\bar{\omega}^* - \bar{\omega}^k=0\)

\(\omega_s^{'k}-\omega_e^k=0\)

The purpose of CCMAV is finding values of \(\omega_s^k\) and \(T_m^k\) satisfying the above equation.

The symbols used are as follows:

\(\bar{\omega}^*\) : Targeted mean angular velocity\(\bar{\omega}^k\) : Mean angular velocity (“k”th cycle)\(\omega_{s}^{'k}\) : Start of the angular velocity\(\omega_{e}^{k}\) : End of the angular velocity\(\omega_{s}^{k}\) : Initial of the angular velocity\(T_{m}^{k}\) : Reverse mean torque acting upon a crank - shaft

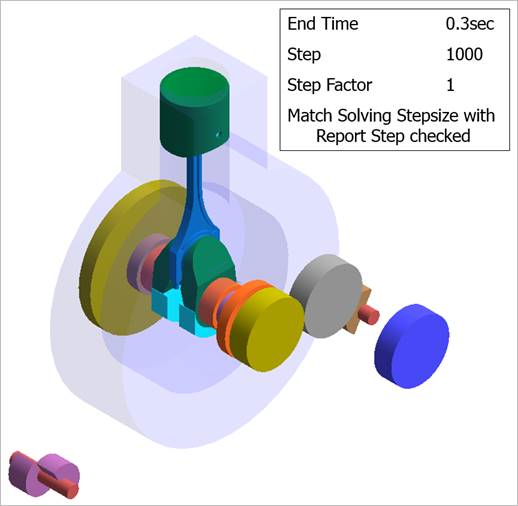

Figure 32.170 The example of CCMAV model

32.4.1. Modeling Options

Create or Open a Crank Model.

Check the Control of Constant Mean Angular Velocity in the Crank System Component Builder dialog box of the Crank toolkit and click OK. Then, the CCMAV force is created in the Database window.

For setting the initial condition by double clicking the CCMAV force or pushing Input in the Crank System Component Builder dialog box.

Set the user-defined parameters by clicking Input.

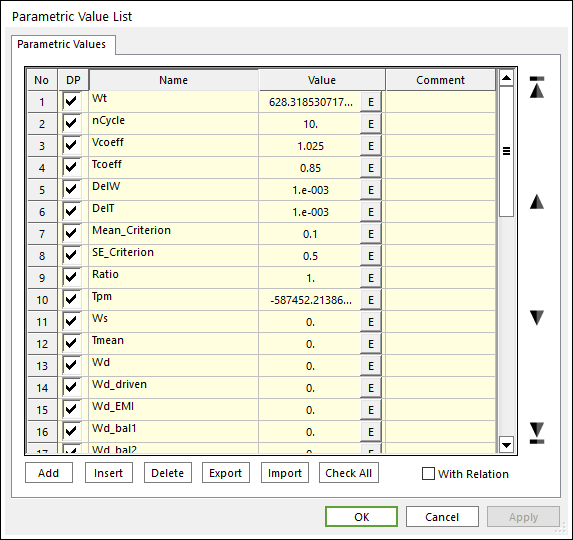

When creating the CCMAV force, the parametric values are created for the setting values at the same time.

Run the simulation by clicking CCMAV

Figure 32.173 CCMAV

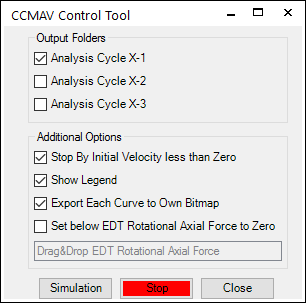

Figure 32.174 CCMAV Control Tool dialog box

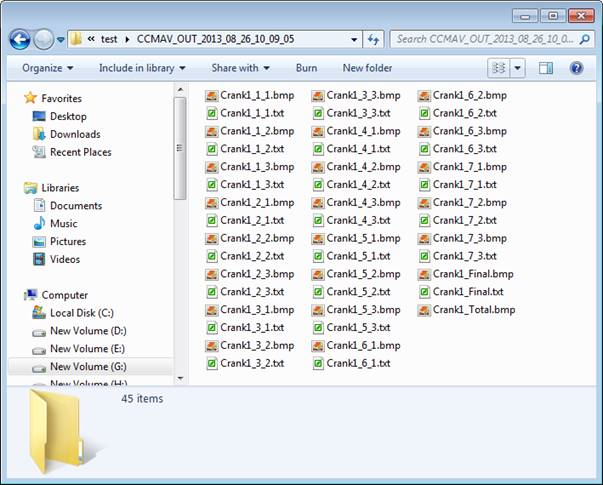

Output Folders: Remains the output folder option

Analysis Cycle X-1: Remains the first analysis output data. If the user does not check this option, the first analysis output data is automatically removed.

Analysis Cycle X-2: Remains the second analysis output data. If the user does not check this option, the second analysis output data is automatically removed.

Analysis Cycle X-3: Remains the third analysis output data. If the user does not check this option, the third analysis output data is automatically removed.

Addition Options

Stop By Initial Velocity less than Zero: An analysis is stopped when the initial angular velocity of the crank shaft is less than zero.

Show Legend: Shows the legend plot data in the post process.

Export Each Curve to Own Bitmap: Exports each curve plot data to own bitmap image file.

Simulation: Starts a simulation

Stop: Stops the simulation

Draw results in Plot automatically and create the output data after finishing the simulation.

The initial velocity and the count torque gotten from the results of CCMAV are applied to the model.

If the user sees the parametric value after completing the simulation, the value gotten from the last analysis is set.

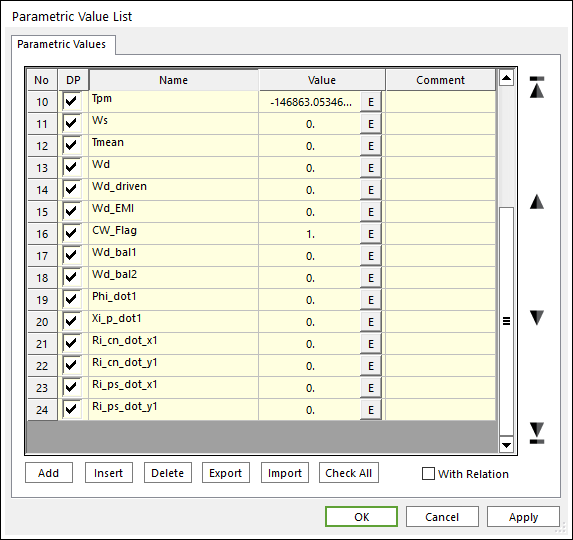

Figure 32.179 Parametric Value List dialog box after simulating

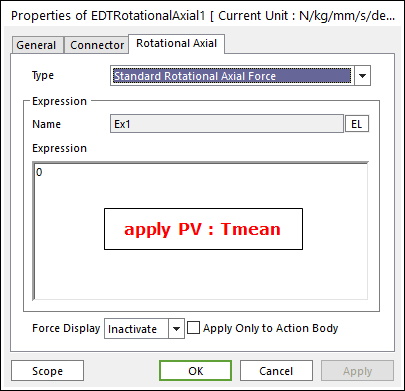

Remove the CCMAV force in the Database window and then input PV: Tmean in Counter Torque Force of the properties of EDT dialog box. If the user does not remove the CCMAV force, the analysis is stopped when passing the rotational range.

Figure 32.180 EDT group dialog box

32.4.2. Properties

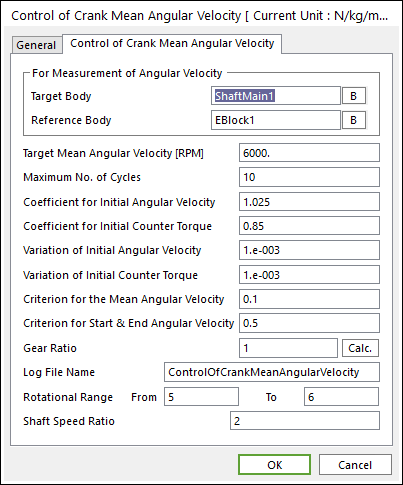

Figure 32.181 CCMAV dialog box

For Measurement of Angular Velocity: Measures the angular velocity of the target body about the reference body.

Target Mean Angular Velocity [RPM]: Inputs the Target Mean Angular Velocity about RPM.(PV : Wt[rad/s])

Maximum No. of Cycles: Sets the maximum value of the cycles. If an analysis is passed to the maximum value, the analysis is stopped. (PV : nCycle)

Coefficient for Initial Angular Velocity: Specifies the setting value of the initial angular velocity (PV : Wt) by multiplying the value of the target angular velocity (PV : Wt) and the coefficient value.

Coefficient for Counter Torque: Specifies the setting value of the Initial counter torque by multiplying the value of the mean torque coming from pressure of a combustion chamber (PV : Tpm) and the gear ratio(PV :ratio), and the coefficient value. (PV : Tcoeff)

Variation of Initial Angular Velocity: Specifies the variation of the angular velocity. (PV : DelW)

Variation of Initial Counter Torque: Specifies the variation of the counter torque. (PV : DelT)

Criterion for the Mean Angular Velocity: Specifies a criterion about the comparison formula of the mean angular velocity. (PV : Mean_Criterion)

Criterion for Start & End Angular Velocity: Specifies a criterion about the comparison formula of the start & end angular velocities. (PV : SE_Criterion)

Gear Ratio: Displays the gear ratio for the drive body when the gear type is Equivalent Drive Train. If the type is the direct type, the value is 1. If the type is the Gear/Belt type, the value is decided by the EDT Driven diameter/EDT Drive diameter. (PV : Ratio)

Log File Name: Displays the name of output files such as [Log File Name]_[Rdyn File Name].log, [Log File Name]_[Rdyn File Name].msg

Rotational Range: Specifies the about the range comparison formula of the mean angular velocity and the comparison formula of the start & end angular velocities. (1 rotation = 360degree) The default value defined from 5 to 6 means to define the range of the comparison formula from 1440 degree to 2160 degree.

CAUTION: If the CCMAV exists, the solver is stopped when passing the rational range. If the analysis is performed after removing the CCMAV in Force of the Database window, the solver is not stopped in spite of passing the rational range.

Shaft Speed Ratio: Specifies the speed ratio among the valve and the timing chain shaft and crank shaft. It is valid to the assembly of the valve and the timing chain subsystem.

32.4.2.1. Parametric Value List about CCMAV

Figure 32.182 Parametric Value List dialog box after creating CCMAV

Tpm: Displays the mean torque coming from the pressure of a combustion chamber.

Ws: Displays the initial angular velocity[rad/s] of the crank shaft for each cycle.(Wt*Vcoeff).

Tmean: Displays to reverse the mean torque action upon the crank shaft. (Tpm*Tcoeff*Ratio).

Wd: Displays the angular velocity[rad/s] of EDT Drive.

Wd_driven: Displays the angular velocity[rad/s] of EDT Driven.

Wd_EMI: Displays the angular velocity[rad/s] of EMI.

Wd_bal: Displays the angular velocity [rad/s] of balancing shaft.

Xi_p_dot: Not used.

Phi_dot: Displays the angular velocity [rad/s] of connecting rod.

Ri_cn_dot_x: Displays the velocity vector about the x component of connecting rod.

Ri_cn_dot_y: Displays the velocity vector about the y component of connecting rod.

Ri_ps_dot_x: Displays the velocity vector about the x component of piston.

Ri_ps_dot_y: Displays the velocity vector about the y component of piston.

CW_Flag: Displays the clock-wise flag(1: clock-wise)