33.3.1.1. Bushing Bearing

A bushing bearing is defined between two bodies. The created position types are two:

Connecting Rod & Piston Pin (CR_PP)

Piston Pin & PisTon (PP_PT)

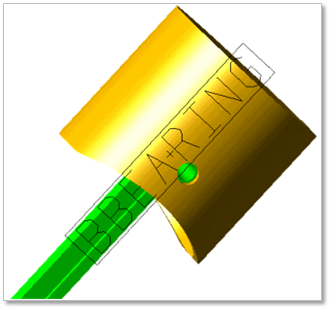

Figure 33.33 Bushing bearing

33.3.1.1.1. Modeling Options

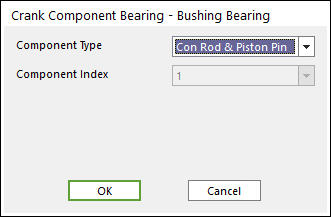

Click the Bushing icon of the Connector group in the Piston tab. The user can see the Crank Component Bearing- Bushing dialog box.

The user can choose the following types in Component Type and select the position where the bushing bearing is created in Component Index.

Figure 33.34 Crank Component Bearing – Bushing Bearing dialog box

Click OK.

33.3.1.1.2. Properties

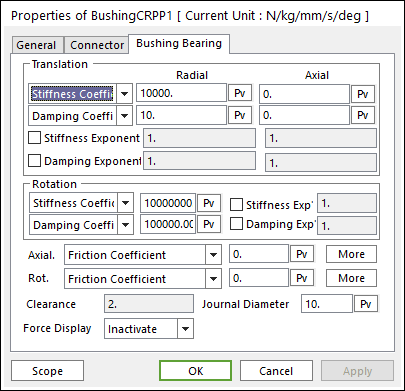

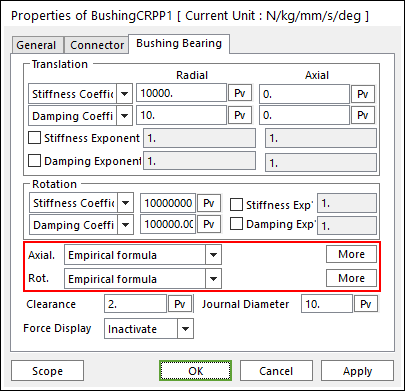

Click the right mouse button on the bushing bearing component to choose Properties of bushing bearing. The user can modify the property of a bushing bearing in following dialog.

Figure 33.35 Bushing Bearing property page

Translation and Rotation: Controls the characteristics of bushing bearing.

Please refer to the Friction types in below.

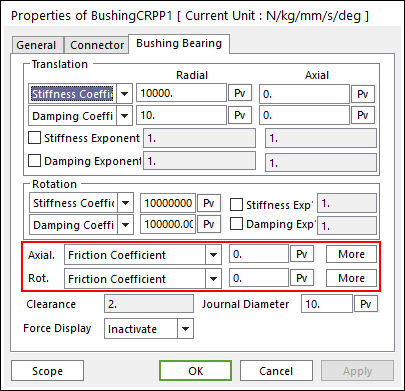

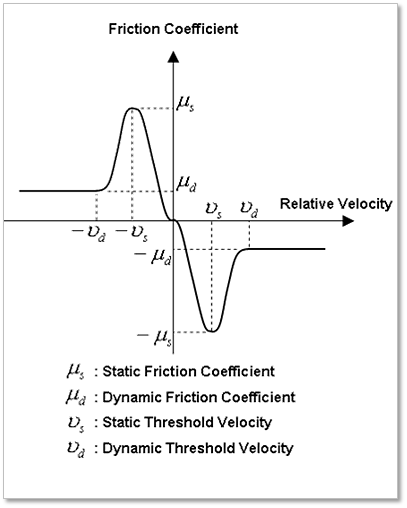

Standard Friction

Select Friction Coefficient in the combo box.

Figure 33.36 Coulomb Friction

Journal Radius: shaft radius attached bearing inside.

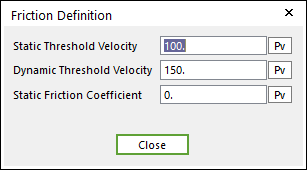

Click More and then enter values to define Coulomb Friction.

Figure 33.37 Coulomb Friction dialog box

Figure 33.38 Standard Friction

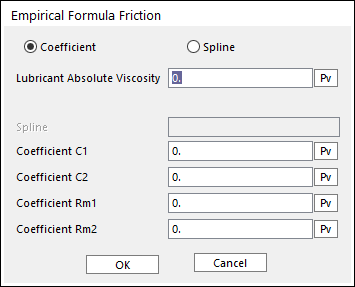

Empirical Formula

Select Empirical formula in the combo box.

Figure 33.39 Empirical formula friction

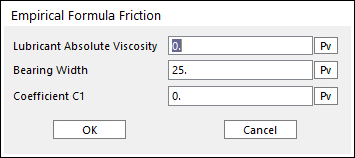

Click More and enter the values to define Empirical Formula Friction.

Figure 33.40 Axial Type Empirical Formula

Figure 33.41 Radial Type Empirical Formula

Friction Torque

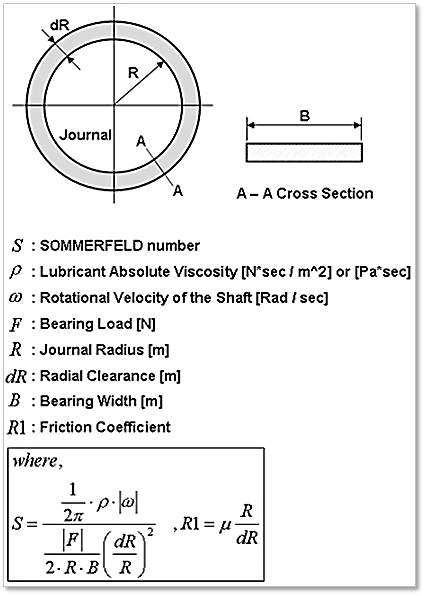

Figure 33.42 Parameters for SOMMERFELD number

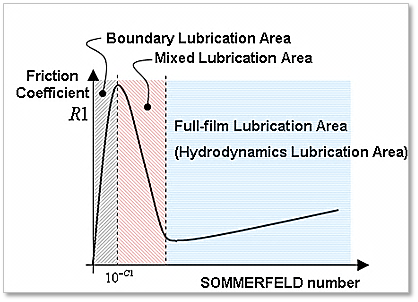

Figure 33.43 Each Lubrication region is decided by the SOMMERFELD number

\(\text{Friction Torque}:T=\sum_i \eta_i F_i R_i (i=1,2,...n)\)

Friction Force

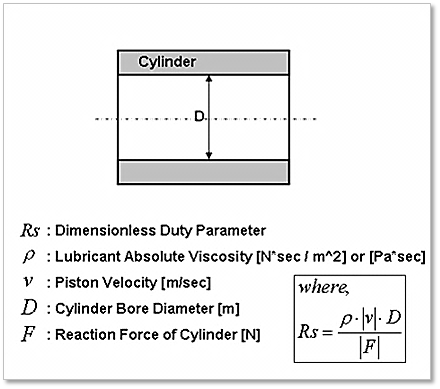

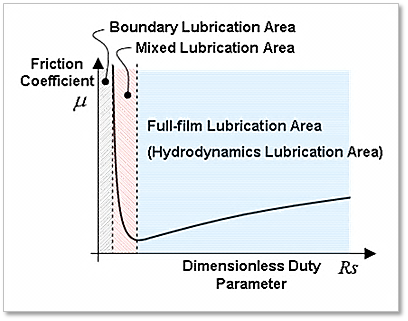

Figure 33.44 Parameters for Dimensionless Duty Parameter

Figure 33.45 Each Lubrication region is decided by the Dimensionless Duty Parameter

\(\text{Friction Force}:F=\sum_i \eta_i F_i (i=1,2,...n)\)