6.4.2.6. Solid

A Solid Contact generates a force between one solid (or available surface for a solid contact) and the other solid (or available surface for a solid contact).

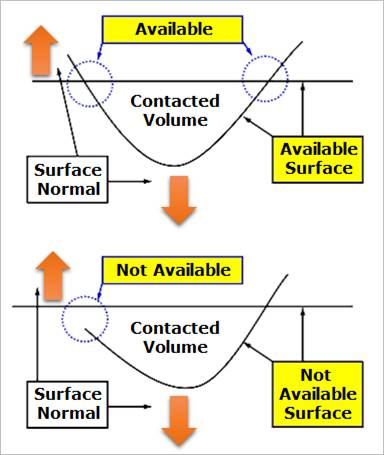

Two solid geometries must belong to two different bodies. And user also uses an available surface instead of solid geometry. But when the user uses a surface instead of solid geometry, the contacted volume must be enclosed during the whole solving time as shown Figure 6.339.

Figure 6.339 Definition of an available surface for a Solid Contact

The contact force can be not only linear or exponential but also nonlinear spline characteristics to the contact penetration and its velocity.

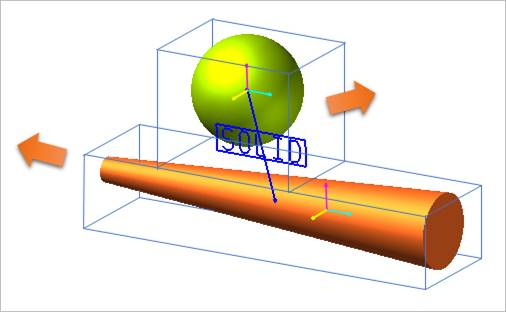

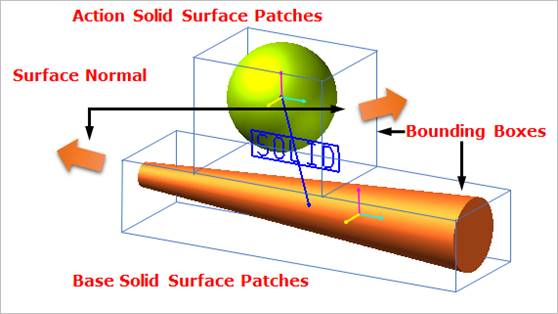

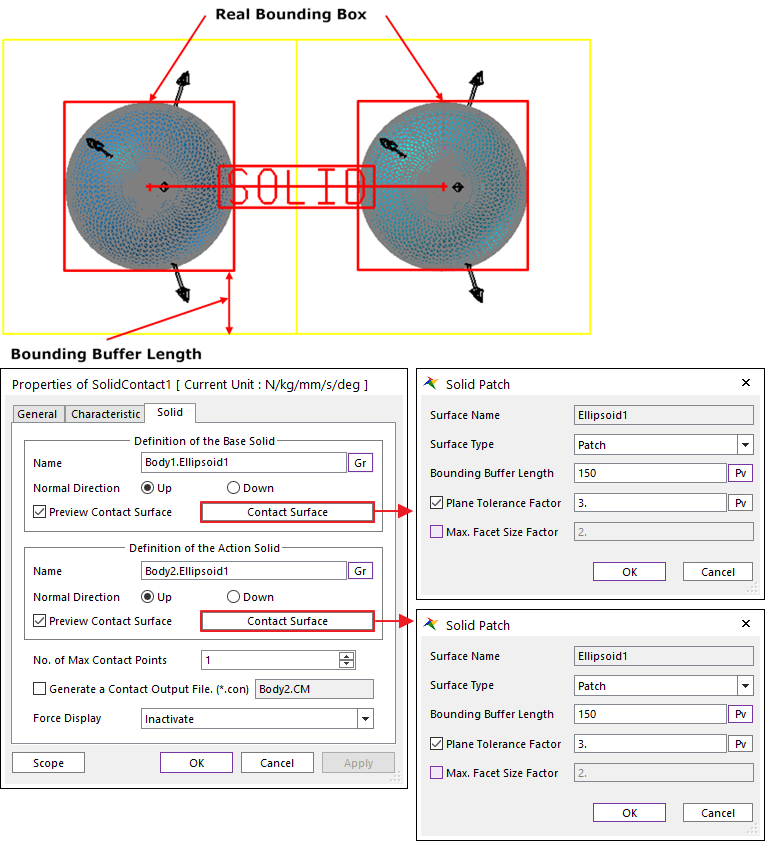

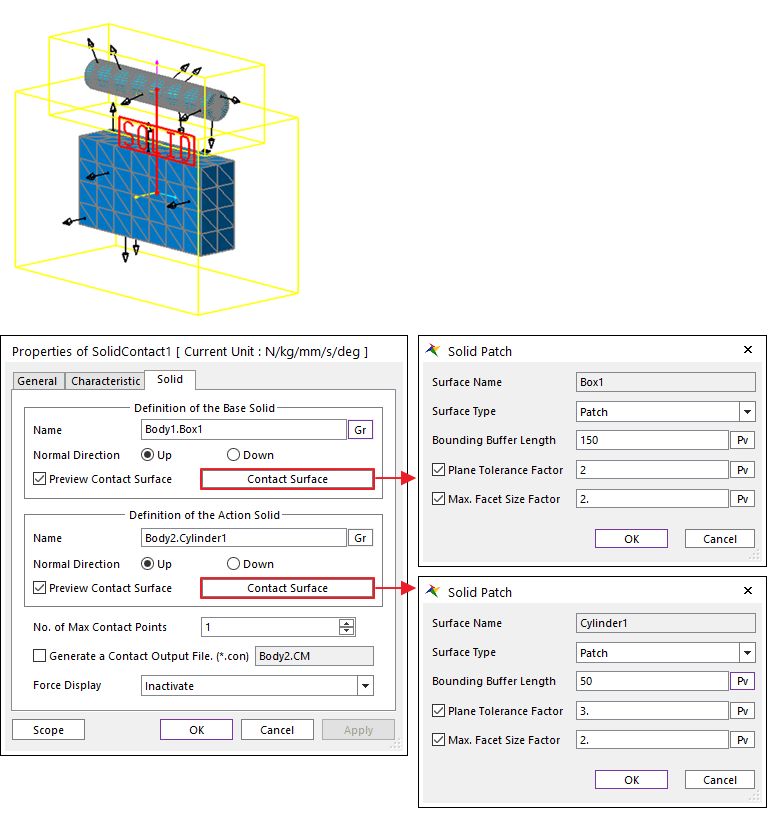

The base solid (or available surface) or action solid (or available surface) can be approximated as multi triangular patches with the Patch option as shown in Figure 6.340.

Figure 6.340 Approximated action and base contact solids

6.4.2.6.1. Modeling Options

In the case of Solid contact, solid, shell, and surface geometry types are supported without base and action geometries when creating.

Solid(Shell), Solid(Shell)

Solid(Shell): Selects a solid or a shell to define a base solid.

Solid(Shell): Selects a solid or a shell to define an action solid.

Solid(Shell), MultiSolid(Shell)

Solid(Shell): Selects a solid or a shell to define a base solid.

MultiSolid(Shell): Selects some solids or shells to define action solids.

Solid(Shell), Solid(Shell), Solid(Shell), Solid(Shell)

Solid(Shell): Selects a solid or a shell to define a base solid.

Solid(Shell): Selects a solid or a shell to define an action solid.

Solid(Shell): Selects a solid or a shell to define another base solid.

Solid(Shell): Selects a solid or a shell to define another action solid.

MultiSolid(Shell), MultiSolid(Shell)

MultiSolid(Shell): Selects some solids or shells to define base solids.

MultiSolid(Shell): Selects some solids or shells to define action solids.

Surface, Surface

Surface: Selects a surface to define a base solid.

Surface: Selects a surface to define an action solid.

Surface, MultiSurface

Surface: Selects a surface to define a base solid.

MultiSurface: Selects some surfaces to define action solids.

Surface, Surface, Surface, Surface

Surface: Selects a surface to define a base solid.

Surface: Selects a surface to define an action solid.

Surface: Selects a surface to define another base solid.

Surface: Selects a surface to define another action solid.

MultiSurface, MultiSurface

MultiSurface: Selects some surfaces to define base solids.

MultiSurface: Selects some surfaces to define action solids.

Solid(Shell), Surface

Solid(Shell): Selects a solid or a shell to define a base solid.

Surface: Selects a surface to define an action solid.

Surface, Solid(Shell)

Surface: Selects a surface to define a base solid.

Solid(Shell): Selects a solid or a shell to define an action solid.

6.4.2.6.2. Properties

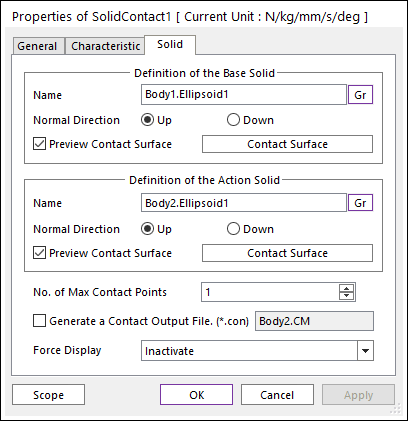

Figure 6.341 Properties of Solid dialog box

Entity Name: Defines the name of base solid (or available surface). The base solid (or available surface) can be dispatched from the Working Window by clicking Gr.

Figure 6.342 Preview of the normal directions, contact patches and nodes

Preview Contact Surface: If this option is checked, the patches making the contact surface are shown on the Working Window as shown in the above figure.

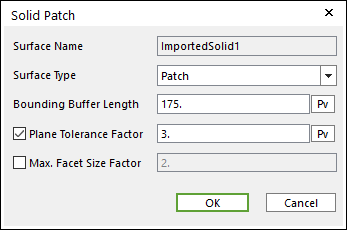

Contact Surface: Accesses the Solid Patch dialog box as shown in the below figure.

Figure 6.343 Solid Patch dialog box

Surface Type: Select only the Patch type for a contact surface. In the Patch type, the contact surface is approximated to multiple triangular patches.

Bounding Buffer Length: Before calculating the collision detection, contact pre-search are performed with base and action bounding box. The bounding buffer length defines the offset length of bounding box compared to the real bounding box as shown in Figure 6.344.

Figure 6.344 Definition of Bounding Buffer Length

Plane Tolerance Factor: Specifies the surface tolerance factor as a value from 0 to 10. A smaller value produces a more refined patch. For more information, click here.

Max. Facet Size Factor: Specifies the max. facet size factor as a value from 0 to 10. This value controls the maximum size of triangular patch length. Even though box geometry, if this value is defined (checked), box geometry can be used with lots of triangular patches as shown in Figure 6.345.

Figure 6.345 Example of Plane Tolerance Factor and Max. Facet Size Factor

No. of Max Contact Point: Defines the number of max contact point.

Generate the contact output file(*.con): When user checks the Generate the contact output file option, RecurDyn creates the contact output file based on the contact output reference marker which can be defined in the contact force page. The user can calculate the local contact information based on the contact output reference by using *.con output file’. Then Recurdyn/Solver reports all contact-related information to the text file. The format is as follows:

Col.

Variables

Descriptions

1

Time

Simulation Time

2

NCP

Total number of calculated contact points

3

NO

Current contact point number

4

X_RefPos

Position X of Output Reference Marker from Global

5

Y_RefPos

Position Y of Output Reference Marker from Global

6

Z_RefPos

Position Z of Output Reference Marker from Global

7

Z_EulerA

Z Euler Angle of Output Reference Marker from Global

8

X_EulerA

X Euler Angle of Output Reference Marker from Global

9

Z_EulerA

Z Euler Angle of Output Reference Marker from Global

10

X_ConPos

Position X of Calculated Contact Reference Frame from Global

11

Y_ConPos

Position Y of Calculated Contact Reference Frame from Global

12

Z_ConPos

Position Z of Calculated Contact Reference Frame from Global

13

X_NorDir

Normal Direction X of Calculated Contact Reference Frame from Global

14

Y_NorDir

Normal Direction Y of Calculated Contact Reference Frame from Global

15

Z_NorDir

Normal Direction Z of Calculated Contact Reference Frame from Global

16

X_TanDir

Tangent(Friction) Direction X of Calculated Contact Reference Frame from Global

17

Y_TanDir

Tangent(Friction) Direction Y of Calculated Contact Reference Frame from Global

18

Z_TanDir

Tangent(Friction) Direction Z of Calculated Contact Reference Frame from Global

19

Pen

Penetration Depth

20

PenVel

Penetration Depth Velocity or Relative Velocity in Normal Direction

21

TanVel

Relative Velocity in Tangent Direction

22

FricCoeff

Friction Coefficient

23

NorForce

Normal Force Magnitude

24

FricForce

Friction Force Magnitude

Force Display: Graphically displays the resultant force vector on the view window.