31.1.10. Worm

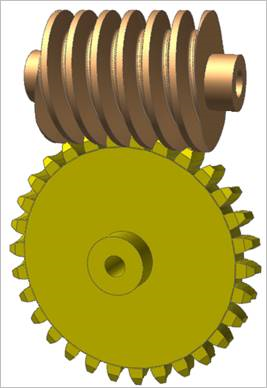

A worm gear is used for transmitting power between two non-parallel and non-intersecting shafts. It is useful when a large speed reduction ration is require between crossed axis shafts. A worm is similar to a screw and a worm gear is similar to a nut. Therefore, if the worm is rotated, the worm gear can be caused to rotate due to the screw like action of the worm.

Figure 31.52 Worm & Worm Gear system

Worm & worm gear are composed of a single body. Gear geometries are created from the parameters of ISO standards. The tooth profile is represented by multiple arcs. The sprocket tooth geometry data is:

Created from a predefined data file

Edited from a predefined data file

Exported from a predefined data file

Imported from a predefined data file

Terminology

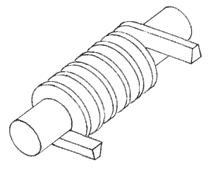

Worm tooth dimensions such as addendum, dedendum, pressure angle, etc. follows the same standards as those for Spur and Helical gears. For more information, refer to Geometric Entities. A worm is regarded as a cylinder with a ridge (V-type shape) wrapped in a spiral around it as shown below.

Figure 31.53 The way to generate a simple Worm

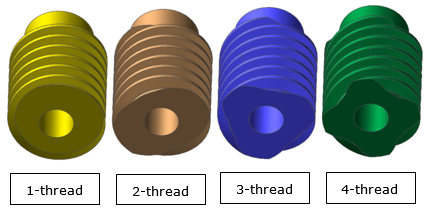

Therefore, a worm can be considered a cylindrical type gear with screw threads. Number of threads (n), which is called Number of Stars in RecurDyn/Gear, in the worm is equivalent to the number of teeth in a gear of a screw type gear mesh. It can be supported form 1 to 4. The number of threads on a worm can be shown by looking at the end and counting the thread starts as shown below.

Figure 31.54 Number of threads of a Worm

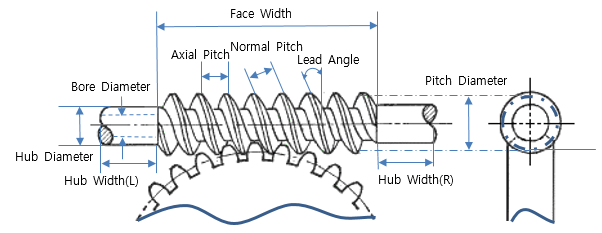

Axial Pitch (Pa) of a worm is a distance measured along the pitch line of the gear. It can be determined by measuring the distance between any corresponding points of adjacent threads parallel to the axis. It is note that the axial pitch of a worm is equal to Circular Pitch (Pc) of the mating worm gear.

Figure 31.55 Worm Terminology

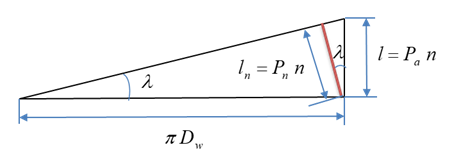

Lead (\(l\)) is the linear distance through which a point on a thread moves ahead in one revolution of the worm. For single start threads, lead is equal to the axial pitch. Therefore, lead can be calculated as the product of axial pitch and number of starts.

\(l\,=\,{{P}_{a}}\,\times \,n\)

Lead Angle (\(\lambda\)) is the angle between the tangent to the tread helix on the pitch cylinder and the plane normal to the axis of the worm. If one complete turn of a worm is imagined to be unwound from the body of the worm, it is from an inclined plane whose base is equal to the pitch circumference of the worm and altitude is equal to lead of the worm, as shown below. In addition, the lead angle is an important factor in determining the efficiency of a worm and worm gear set. Therefore, the efficiency increase as the lead angle increases.

Figure 31.56 Lead and Lead Angle

\(\begin{aligned} & \tan \lambda =\,\frac{l}{\pi {{D}_{w}}}\,=\,\frac{{{P}_{a}}\,n}{\pi {{D}_{w}}}\,=\,\frac{{{P}_{c}}\,n}{\pi {{D}_{w}}} \\ & \,\,\,\,\,\,\,\,\,\,\,\,=\,\frac{\pi {{m}_{a}}n}{\pi {{D}_{w}}}\,=\,\frac{{{m}_{a}}\,n}{{{D}_{w}}}\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,\,(\,\because \,{{P}_{a}}\,=\,{{P}_{c}}\,) \\ \end{aligned}\)

where \({{m}_{a}}\) is Axial Module, \({{D}_{w}}\) is Pitch Diameter of the worm.

Normal Pitch (Pn) of a worm is a distance measured along the normal plane which is the plane normal to the tooth surface at a pitch point and perpendicular to the pitch plane as shown in Figure 31.56.

\({{P}_{n}}\,=\,{{P}_{a}}\,\times \,\cos \lambda ,\,\,\,{{m}_{n}}\,=\,{{m}_{a}}\,\times \,\cos \lambda\)

where \({{m}_{n}}\) is Normal Module which is called just Module in Worm and Worm Gear of RecurDyn/Gear. This is the input value to make them.

The term normal pitch is used for a worm having single start threads. In case of a worm having multiple start threads, the term normal lead (\(l\)n) is used as follows.

\({{l}_{n}}\,=\,l\,\times \,\cos \lambda\)

Diameter Factor (Q) means Pitch Diameter of worm (Dw) over axial module (ma). It is effective to use this factor when defining a Worm Gear meshing user-defined Worm because the Number of Start option in the worm dialog box doesn’t work if Lead Angle is selected.

\(Q\,=\,\frac{{{D}_{w}}}{{{m}_{a}}}\)

For more information, refer to Geometric Entities.

31.1.10.1. Properties

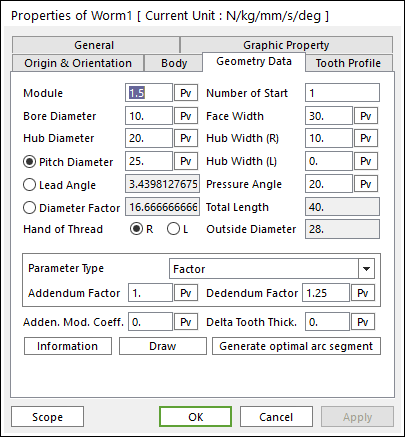

Figure 31.57 Worm property page [Geometry Data page]

The Worm property page is shown in Figure 31.57. The parameters are explained below.

Module: Enters the module of the gear.

Number of Start: Enters the number of threads on the worm. For more information, click here.

Bore Diameter: Enters the bore diameter of the worm.

Face Width: Enters the face width of the worm.

Hub Diameter: Enters the hub diameter of the worm.

Hub Width (R): Enters the hub width for the right of the worm.

Hub Width (L): Enters the hub width for the left of the worm.

Pressure Angle: Enters the pressure angle of the gear.

Total Length: Shows the total length of the worm.

Pitch Diameter: Enters the pitch diameter of the worm. This can define a lead angle. For more information, click here.

Lead Angle: Enters the lead angle of the worm. This can define a pitch diameter. For more information, click here.

Diameter Factor: Enter the factor for Pitch Diameter. This can define a pitch diameter and lead angle. For more information, click here.

Hand of Thread: Defines the direction of thread as L or R.

Outside Diameter: Shows the outside diameter of the worm.

Parameter Type: two methods are supported to define the Addendum and Dedendum.

Factor: Defines the addendum and dedendum as factors. For more information, click here.

Addendum Factor: Enters the factor to define the addendum.

Dedendum Factor: Enters the factor to define the dedendum.

Addendum Radius & Whole Depth: Defines the addendum and dedendum as addendum radius and whole depth. For more information, click here.

Addendum Radius: Enters the addendum radius for the gear.

Whole Depth: Enters the whole depth as summation for the addendum and dedendum.

Adden. Mod. Coeff.: Enters the coefficient to define the addendum.

Delta Tooth Thick.: Enters the delta value to define the tooth thickness. For more information, click here.

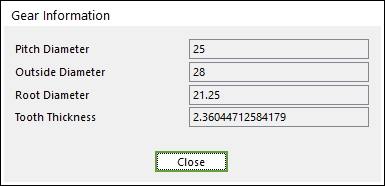

Information: Shows the calculated values for Pitch Diameter, Outside Diameter, Root Diameter, and Tooth Thickness.

Figure 31.58 Gear Information dialog box

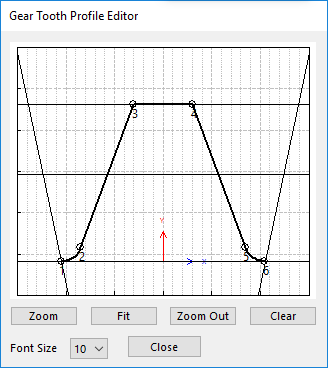

Draw: All data must be defined with respect to the tooth marker. You can move points graphically by using the mouse directly.

Figure 31.59 Gear Tooth Profile Editor dialog box

Generate optimal arc segment: In order to apply the modification of tooth, this button should be clicked.