14.2.2.2. Life Criteria

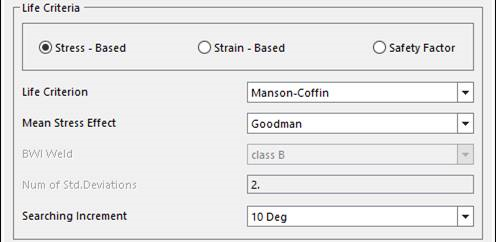

Figure 14.10 Fatigue Evaluation dialog box

You can select one of the following life criteria for fatigue evaluations.

Stress-based life criteria

Manson-Coffin

Morrow

ASME boilers and pressure vessels

BWI (BS7608)

Weld life criteria for fatigue damage assessment and life prediction

User-Defined

Strain-based life criteria

Manson-Coffin

Morrow

Smith-Watson-Topper

Maximum Shear Strain

Brown-Miller

User-Defined

Safety factor

Goodman safety factor

Gerber safety factor

Modified Goodman safety factor

For the selection reference of Life criteria, the user can refer to the Table 14.1. Also, if the user wants to get more information about Life criteria, the user can refer to the Theory of RecurDyn/Durability.

Mean Stress Effect

Mean stress effect is only available on Stress-based life criteria. To get detail information related to this effect, please refer to ‘Stress Life Criteria’ in the Theory of RecurDyn/Durability.

Searching Increment

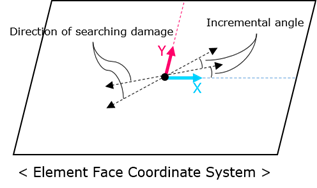

In the maximum damage approach which is one of the Fatigue evaluation methods, RecurDyn/Durability calculates the uni-axial and bi-axial damage using the stress or strain history in different directions on element faces. The directions on element face are defined by using the user-defined incremental angle as shown in the Figure 14.11. At this point, Element Face coordinate system is the coordinate system defined on each element face which has the normal direction (Z-axis) perpendicular to each element face. So, if the incremental angle is smaller, the damage results increase because of more directions to calculate and it takes longer to calculate the fatigue results.

Please refer to of Maximum Damage Approach of ‘Fatigue Evaluation Methods on Element face’ in the Theory of RecurDyn/Durability to get more information.

Figure 14.11 Definition of Incremental Angle